Using Tumoshi’s photothermal method for non-contact thickness measurement, the dry film thickness can be obtained by measuring the wet film before the product enters the oven, so that the process parameters can be adjusted in time, the defective rate is greatly reduced, and the process flow is optimized.

At present, most painting workshops use a dry film thickness meter to test the dry film thickness after the product coating is dried to control the quality of the product film thickness. However, when the film thickness is found to be unqualified, a large number of defective products cannot be avoided. And if you want to adjust the spraying equipment at this time, you can only know whether the adjustment is in place after measuring the dry film thickness after drying.

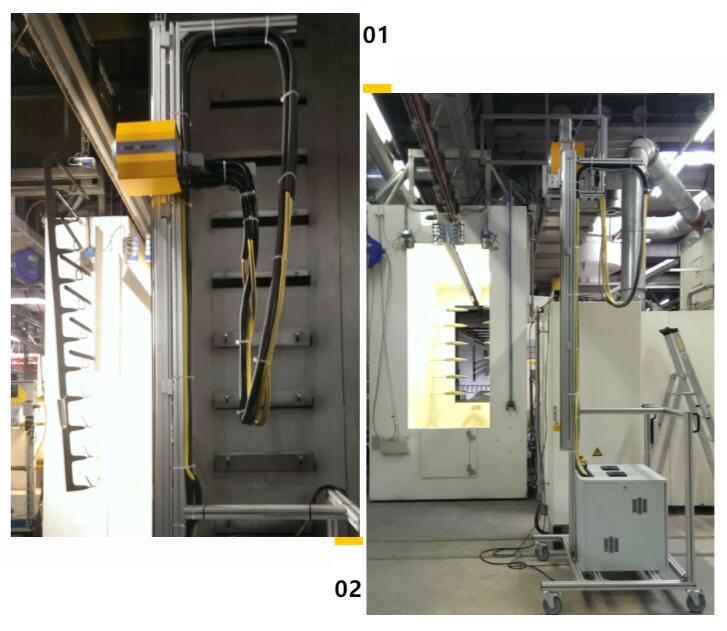

Online non-contact non-destructive thickness measurement system

Now, using the photothermal method for non-contact thickness measurement, the dry film thickness can be obtained by measuring the wet film before the product enters the oven, so that the process parameters can be adjusted in time, the defective rate can be greatly reduced, and the process flow can be optimized. The non-contact non-destructive thickness measurement system Tumagist from Switzerland has realized the function of testing the undried paint film in real time to obtain the dry film thickness:

1. One-key test, allowing complex shapes and angles of the product to shake and tilt: effectively avoid human-made measurement errors;

2. Unlimited substrate materials (all kinds of metals, plastics, glass, wood, rubber, etc.), unlimited coating types (paints, powder coatings, adhesives, lubricating coatings, etc.);

Handheld Non-Contact Film Thickness Analyzer

3. High precision, non-contact film thickness measurement, better than dry Film Thickness Gauge;

4. Data recording and process traceability: real-time monitoring and feedback of product film thickness of the production line, and 100% data archiving;

5. Non-hazardous: The harmless light source is used, and there is no harm to the human body and products.

The thickness measurement system effectively improves the accuracy of the operator in adjusting the spraying equipment, provides real-time feedback on the status of the process, reduces rework and customer dissatisfaction, and reduces production costs.

Using Tumoshi’s photothermal method for non-contact thickness measurement, the dry film thickness can be obtained by measuring the wet film before the product enters the oven, so that the process parameters can be adjusted in time, the defective rate is greatly reduced, and the process flow is optimized.

Using Tumoshi’s photothermal method for non-contact thickness measurement, the dry film thickness can be obtained by measuring the wet film before the product enters the oven, so that the process parameters can be adjusted in time, the defective rate is greatly reduced, and the process flow is optimized.

At present, most painting workshops use a dry film thickness meter to test the dry film thickness after the product coating is dried to control the quality of the product film thickness. However, when the film thickness is found to be unqualified, a large number of defective products cannot be avoided. And if you want to adjust the spraying equipment at this time, you can only know whether the adjustment is in place after measuring the dry film thickness after drying.

Online non-contact non-destructive thickness measurement system

Now, using the photothermal method for non-contact thickness measurement, the dry film thickness can be obtained by measuring the wet film before the product enters the oven, so that the process parameters can be adjusted in time, the defective rate can be greatly reduced, and the process flow can be optimized. The non-contact non-destructive thickness measurement system Tumagist from Switzerland has realized the function of testing the undried paint film in real time to obtain the dry film thickness:

1. One-key test, allowing complex shapes and angles of the product to shake and tilt: effectively avoid human-made measurement errors;

2. Unlimited substrate materials (all kinds of metals, plastics, glass, wood, rubber, etc.), unlimited coating types (paints, powder coatings, adhesives, lubricating coatings, etc.);

Handheld Non-Contact Film Thickness Analyzer

3. High precision, non-contact film thickness measurement, better than dry Film Thickness Gauge;

4. Data recording and process traceability: real-time monitoring and feedback of product film thickness of the production line, and 100% data archiving;

5. Non-hazardous: The harmless light source is used, and there is no harm to the human body and products.

The thickness measurement system effectively improves the accuracy of the operator in adjusting the spraying equipment, provides real-time feedback on the status of the process, reduces rework and customer dissatisfaction, and reduces production costs.

technology application

Application 1: Making high-level prototypes

When sending samples to customers, it is necessary to prepare samples within the specified film thickness range, with uniform film thickness and consistent color. Therefore, after the production enterprise uses the magician when making the swatches, it is very convenient to know whether the film thickness of the swatches is qualified before drying, and there is no need to go back and forth to rework.

Application 2: Measure the wet film to obtain the dry film thickness immediately

When spraying paint for home appliances or auto parts, if the film thickness is too thick, the product coating is easy to burst, the color is uneven, and there are defects such as orange peel and flow marks; if the film thickness is too thin, there will be poor hiding power, and the surface of the paint film will Muscle-like wrinkles, color and gloss will also be affected. Use Tumagist to test the wet film non-contact on the production line to obtain the dry film thickness in real time, effectively monitor the film thickness in real time, and realize statistics and traceability of the production process.

Application 3: Timely detection of Spray Gun or equipment failure

When the coating thickness is higher than the qualified value, it may be considered to reduce the amount of coating to save production costs. When the film thickness exceeds the set qualified value, the applicator will send out an alarm signal, adjust the powder output in time, improve the yield rate, reduce the rework rate, and reduce environmental risks. When the qualified range cannot be reached through manual intervention and adjustment, the applicator can detect the failure of the Spray Gun or equipment in time, repair the failure, improve production efficiency and stabilize quality.

It can be seen that the non-contact non-destructive testing of the wet film thickness before entering the oven can not only effectively stabilize the quality of the spraying process, but also greatly save manpower, time loss and production costs.

Tumoshi non-contact non-destructive Thickness Gauge customer case

Case 1: The use of a familiar spraying manufacturer

After a well-known spraying manufacturer in foreign countries uses TuMashi, the fluctuation of the coating thickness value that was originally outside the qualified line was adjusted to within the qualified line (as shown in the figure below), so as to realize the optimization of production line and product quality.

Case 2: On-site test of the coating production line of a domestic aluminum profile factory

1. Customer issues

The eddy current Thickness Gauge was used to measure the coating thickness of the cured aluminum profile, and it was found that the spraying quality was not good, and the coating thickness of some sprayed areas exceeded the qualified value or the film thickness was uneven, which required rework.

2. Improvement measures

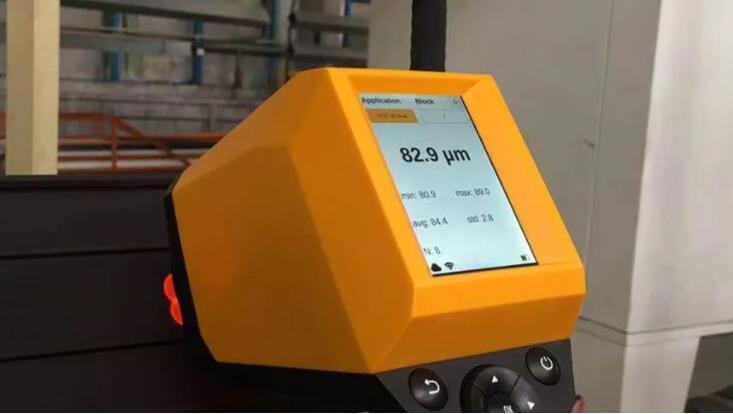

Using the handheld non-contact film thickness analyzer Tumoshi flex, you can know the film thickness of the product before the product enters the oven, and adjust the spraying equipment in time to reduce the defective rate. Use Tumoshi non-contact film thickness analyzer and dry Film Thickness Gauge to compare and test at the same position on the aluminum profile, and the difference in test data is less than 5 microns. Moreover, the repeatability and precision of the Tumagist Flex are better.

3. Final problem solving

① Monitor the film thickness in real time, and test the uncured powder coating to obtain the cured film thickness;

② Timely discovery of the clogging of the Spray Gun;

③ Know in real time whether workers have adjusted the powder spraying equipment;

④ Save powder.

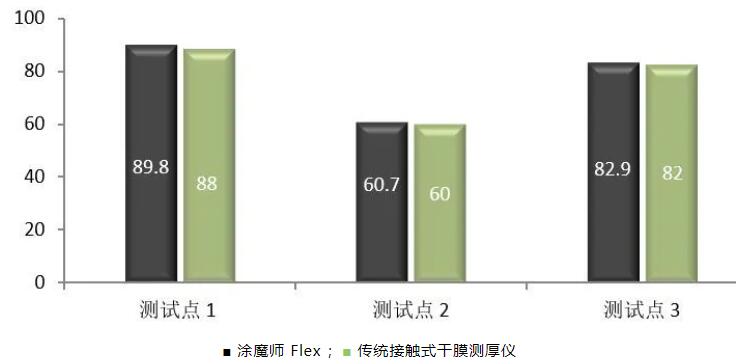

4. On-site testing

Traditional Contact Film Thickness Gauge VS. Handheld Non-Contact Film Thickness Analyzer Tumoshi Flex

first group comparison?

Painter Flex: 89.8 microns

Traditional contact dry Film Thickness Gauge: 88 microns

The second group comparison?

Painter Flex: 60.7μm

Traditional contact dry Film Thickness Gauge: 60μm

The third group comparison?

Painter Flex: 82.9μm

Traditional contact dry Film Thickness Gauge: 82μm

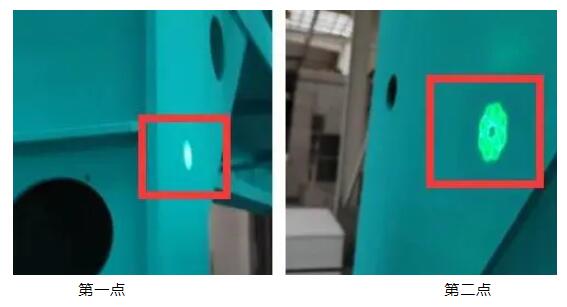

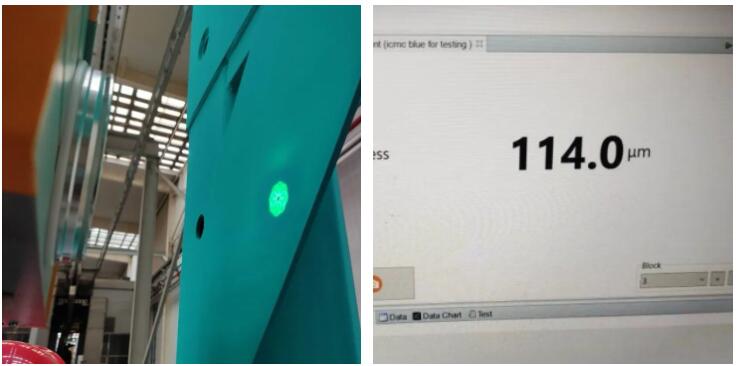

Case 3: On-site test of a domestic special vehicle coating production line

| test point | point 1 | point 2 |

| Painter | 137.2 | 110 ~114 |

| Dry film thickness meter | 136 | 114 |

| 138 | 113 | |

| 135 | 110 | |

| 134 | 114 | |

| 142 | 113 | |

| average value | 137 | 112.8 |

The first point

Tumoshi non-contact thickness measurement system - measuring film thickness before curing

Traditional Dry Film Thickness Gauge - Measuring Film Thickness After Curing

Second point

Tumoshi non-contact thickness measurement system - measuring film thickness before curing

Traditional Dry Film Thickness Gauge - Measuring Film Thickness After Curing