Synergistic Paint is not a "paint" in the traditional sense. They are created to combine the advantages of anodizing or hard coat plating with the controlled infusion of low friction polymers and/or dry lubricants. These "coatings" become part of the integral top layer of the base metal, not just a surface covering. Because the resulting surfaces outperform the base metal and the individual components of the coating, the proprietary process that produces them is considered "synergistic." Why do they work?

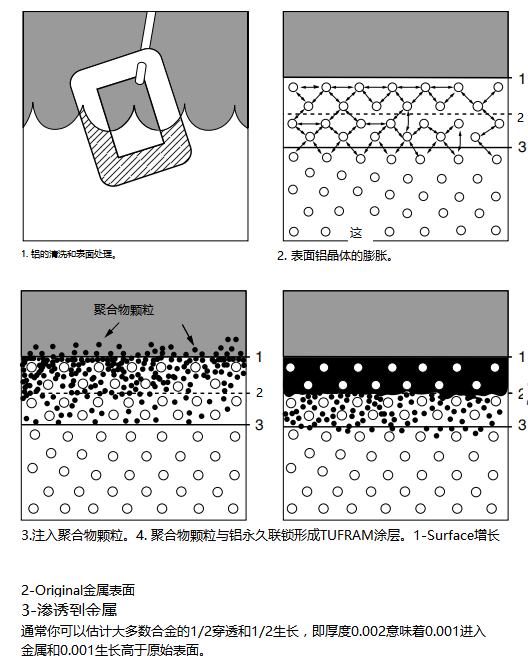

The Tufram process is a series of coatings on aluminum alloys that convert hydrated alumina to Al2O3 H2O and replace the H2O of the newly formed ceramic surface with an inert polymer material to provide a self-lubricating surface. During this process, the aluminum crystals expand and form porous anchors that hold the crystals hygroscopic for a short time. Particles of the particular polymer selected are then introduced under suitably controlled conditions.

Equilibrate solutions, time and temperature to permanently interlock with newly formed crystals. This results in a continuously lubricated plastic-ceramic surface that is harder than steel, of which the polymer particles become an integral part.

Figure 35.1 Tufram Process Sequence

Synergistic coatings are a great asset in solving many wear problems, but how were these problems solved years ago? Their solutions are expensive, time-consuming and very frustrating.

Typically one face is made of 0.005 to 0.020 inch hard chrome and then precision machined to a specification. When that surface is polished to 4 RMS or better, it's basically a worn surface because it's hard, and a 4 RMS micropolish lowers the coefficient of friction. If the coefficient compares the coefficient of friction of such a surface with that of a synergistic coating (see Table 35.1), the latter will be considered to have a much lower figure and therefore a lower friction value. It is important to be familiar with the coefficient of friction between materials. Table 35.1 gives the static and dynamic coefficients of friction for a number of base coatings. Each decimal represents the frictional force applied on the two surfaces.

The coefficients in Table 35.1 are for information only. Many factors can vary the numbers derived from these laboratory constants, including the following:

• Applied load

• point loading

• Loading stress

• Substrate hardness

• temperature conditions

• Presence of ambient humidity

• environmental change

• Micro-finished components

Due to the complexity of wear and friction phenomena, all these conditions need to be considered when designing any system.

All tests were standardized as follows:

1. Samples are ground and polished to 4 to 6 RMS.

2. The laboratory temperature is maintained at 72°F and the relative humidity is 54%; absolute humidity of mercury. 10.6.

3. Take an average of five readings per test run.

4. TMI uses a Slip and Friction Tester (Model 98.5) with a constant load of 200 g.

5. See Table 35.2 for materials and coatings.

6. The friction Tester used was a TMI Slip and Friction Tester Model 98-5, using a constant 200 gram load. As shown in Figure 35.2.