Typically, an effective surface treatment is chemical etching of the plastic to be coated. Both can alter physical and chemical properties to improve wetting and film adhesion. Almost always, chemical treatment is preceded by one or more cleaning operations to remove surface contamination. These prior manipulations reduce solution contamination and ensure better interaction between solution and substrate.

Sulfuric acid-dichromate etching

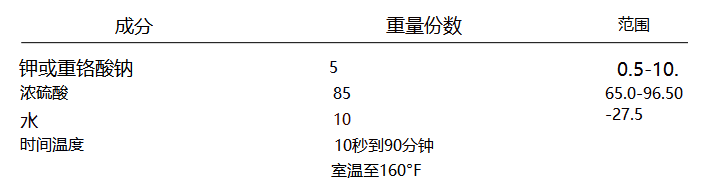

So far the common chemical treatment of plastic parts is sulfuric acid-dichromate etchant for acrylonitrile-butadiene-styrene (ABS), acetal, melamine or urea, polyolefins, polyphenylene ether , polystyrene, polysulfone and styrene-acrylonitrile (SAN). For each plastic, different ingredient ratios and soak temperatures and times may be recommended. The following list is provided as a guide to possible parameter ranges:

While the range is very broad, experimental trials combined with test results will allow the user to determine more appropriate values for a given plastic.

Sodium etching

For really difficult surfaces to coat, such as various fluoroplastics and some thermoplastic polyesters, highly reactive materials are required. Sodium metal (2 to 4 parts) is dispersed in naphthalene (10 to 12 parts) and tetrahydrofuran (85 to 87 parts). The soaking time is about 15 minutes at ambient temperature, followed by the solvent (ketone) before rinsing with water .

sodium hydroxide

A mixture of 20 parts by weight sodium hydroxide and 80 parts by weight water is an effective treatment for thermoplastic polyesters, polyamides and polysulfones. Heating the solution to 175 to 200°F and soaking for 2 to 10 minutes is suitable.

polished

Buffing is a process developed by DuPont for its homopolymer grade acetal (US Patent 3,235,426). Immerse the part in a heated solution of dioxane, p-toluenesulfonic acid, perchlorethylene, and thickener. After the immersion cycle, the parts are heat treated, rinsed and dried according to the following regulations. prescribed procedures.

phenol

Nylon is usually etched with 80% phenol in water. Generally, the treatment is to come to room temperature by brushing on the surface and drying at about 150°F for about 20 minutes.

sodium hypochlorite

Many plastics, especially thermoplastics and newer thermoplastic rubbers, can be chlorinated on surfaces by using a solution (parts by weight) of the following ingredients:

Water: 95 to 97

Sodium hypochlorite, 15%: 2 to 3

Concentrated hydrochloric acid: 1~2

Parts can be soaked at room temperature for 5 to 10 minutes, or the solution can be brushed onto the surface for the same period.