One of the problems associated with trying to process polyolefins with inline burners is the requirement for films to increase the flame velocity enough to penetrate the boundary air layer rather than the web surface. In order to treat a substrate with a direct flame, sufficient thermal energy needs to be developed to penetrate this layer. In addition, the outlet velocity of the burner flame needs to be adjusted to different network speeds.

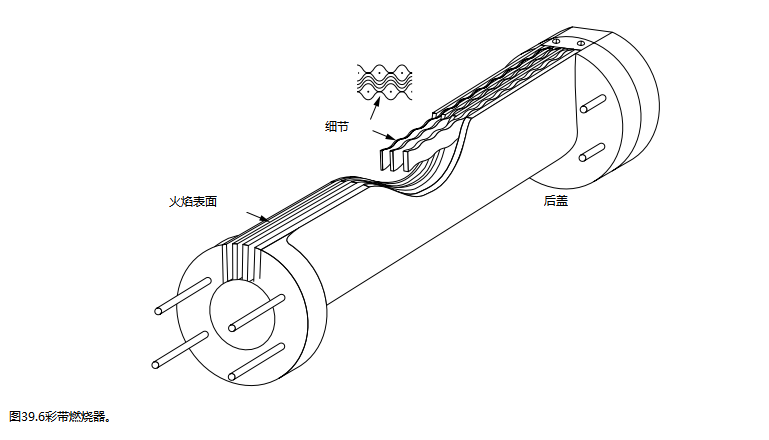

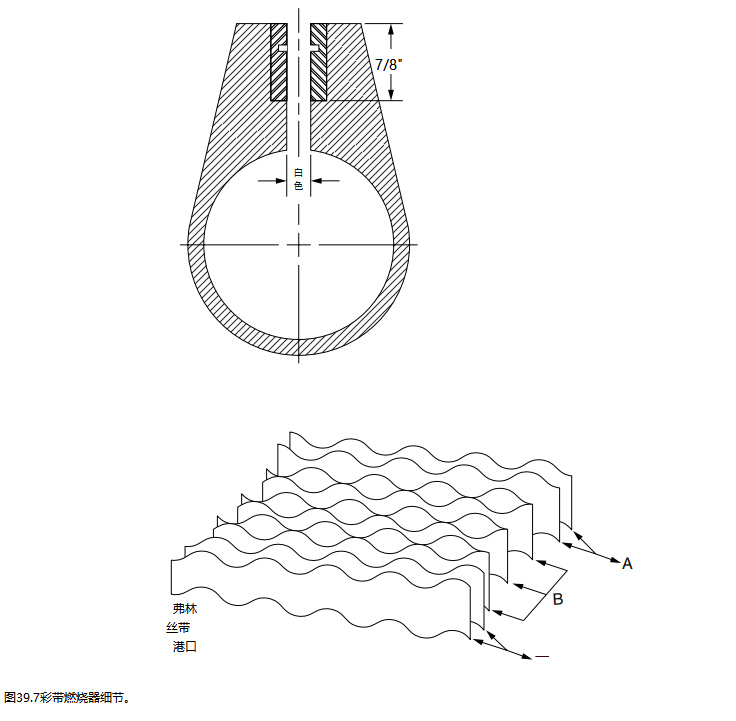

The principle of burner design to meet these requirements is shown in Figure 39.8. Pilot or ignition flame channels where ribbons ignite at reduced exit velocities provide a constant supply to the ignition central ribbon channel, enabling ignition flame propagation at exit velocities well in excess of normal , greatly increasing the energy output of the burner.

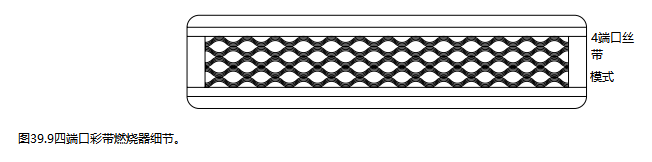

Figure 39.9 shows a burner designed for thin film reprocessing applications. It has a slot because of the lower power output requirement. Water cooling is built into the face. Side bars ensure a smooth flame, which is necessary for the aftertreatment process. Capacity, flame speed and flame retention functions are all related to the functional zone configuration. By varying the number of ports and the width of the ribbon stack, a custom flame pattern can be produced for each application.