When designing, applying, and monitoring coatings, ensuring the integrity of the protective coating is absolutely critical. Without knowing what the coating can withstand, there is a high risk of the coating failing. Testing the mechanical properties of a coating is one of the ways to ensure that the coating in question can handle the environment and operating conditions in which it is exposed.

There are many tests that allow for many different measurements of the strength and other properties of a coating. Understanding the various tests and how they can be used to determine the quality of a coating is a key factor in improving the chances of a successful project. While many tests have been designed, they generally fall into the following four categories.

Coating hardness test

Hardness is a mechanical property that helps a coating resist indentation. Harder coatings have a stronger ability to withstand dents. When indentation is an issue, it is worth using a coating Hardness Tester to verify that the cured coating is at the desired hardness level.

The Buchholz Indentation Tester is the best way to perform this validation. During the Buchholz indentation test, a standard-sized tool is pressed against the cut for a period of time under constant load. Once the time has expired, the tool is removed and the indentation is measured. The larger the size of the indentation, the lower the hardness of the coating.

Coating abrasion test

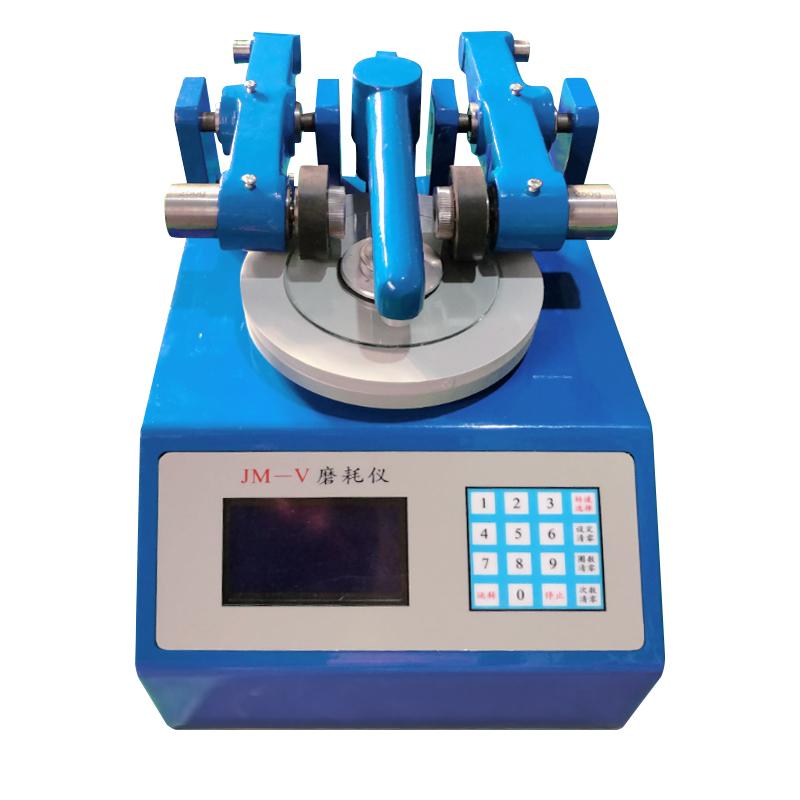

Abrasion of the coating occurs when all or part of the coating is scraped off by another material, which is obviously undesirable because it leaves the base material unprotected after the coating has been removed. Therefore, it is necessary to carry out a wear test to see how the coating holds when it comes into contact with the other object when two objects are moving relative to each other.

A common test used to determine the abrasion resistance of a coating is the Taber test. To perform the Taber test, the evaluated coating material is applied to a solid flat plate. After the coating has cured, the plates are loaded into the testing machine. The grinding wheel is placed on the coating and moves over the surface of the plate for a predetermined period of time. As the grinding wheel travels along the coated surface, this movement gradually removes the coating material. The weight of the specimen before and after the test is then used to calculate the abrasion resistance of the coating.

Another less scientific way to know the indentation and abrasion resistance of a coating is to conduct what is known as a nail test. To perform this test, after the coating has cured, a nail (or other object with a well-defined edge, such as a coin or knife) is dragged across the surface of the coating. Once done, evaluate the coating surface to determine if any damage has occurred. If excessive damage is done to the coating, then it will be considered unsatisfactory. If the movement of the nail or other edge type on the coated surface seems to have little or no effect, it is considered acceptable.

Because the force exerted by the nail on the coating is not measured, and the sharpness of the nail is not captured, nail testing methods are usually only suitable for basic field testing. If numerical data is required for coating wear testing, a more appropriate evaluation method is the Taber wear test.

Coating adhesion test

The ability of the coating to adhere to the substrate is very important, as without sufficient adhesion, the coating can peel off completely prematurely, exposing the substrate to the environment.

A common test used to determine the adhesive strength of a coating is the peel adhesion test. To perform this test, a special pull-off gauge is required. The gauge is attached to the adhesive pad or trolley, which is then attached to the coating. A force is then applied to pull the trolley away from the coating. The amount of force applied is recorded until a coating failure occurs. This force is used in conjunction with the area measurement of the trolley to determine the adhesive strength of the coating.

Since coating adhesion is such an important consideration, there are other tests to measure this mechanical property in addition to the peel adhesion test. Another method for determining the bond strength of a coating is the tape adhesion test, which is a popular method for evaluating coatings for field applications when no other more digital options are available. To perform the tape adhesion test, a part of the coating attached to the substrate is cut with a sharp object. The tape is then applied to the coated area that has been cut. Remove the tape in a quick way and evaluate the amount of coating material removed. Although it does not provide much quantifiable data, it can be helpful to quickly assess the adhesive strength of the coating to a certain extent.

Coating flexibility testing

When a coating is applied to a substrate that will be deformed, the coating needs to be able to withstand the deformation of the material without failing. Some coatings are hard and brittle, so they are unlikely to remain intact when the substrate begins to bend.

Testing the flexibility of coatings can help prevent such coating failures from occurring. A common way to test the stiffness of a coating is to apply a coating to the substrate, allow it to cure, and then bend the substrate and coating around the mandrel. The diameter of the mandrel is selected based on the amount of deformation that the coating is expected to withstand in the actual application. If there are cracks or chips, it is likely that the coating is not flexible enough to serve its intended purpose.