Many types of instruments are available to measure viscosity. There are two basic scientific devices that divide the field of rheology (the study of material deformation or flow behavior) into kinematics or dynamic flow. The former utilizes a capillary viscometer—a vertically oriented glass tube in which gravity drives fluid flow downward—to measure the transit time between two reference points on the tube. The latter rotates a spindle immersed in the sample material and measures the torque resistance (see Figure 1).

The general industry prefers Rotational Viscometers due to their ease of use and rapid testing capabilities. Key questions to answer when considering the appropriate type of Rotational Viscometer include:

How much sample material is available for testing?

Does the broad shear rate used in the test method matter?

Is temperature control of the sample required?

How many samples need to be tested?

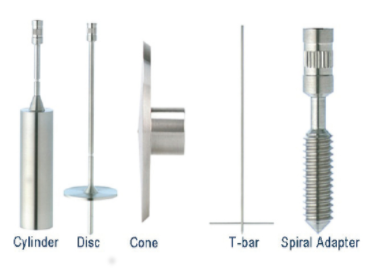

The answers to these questions may determine the choice of spindle type for viscosity measurement. Figure 2 shows various rotors found in the laboratory. Each has a recommended sample size for viscosity testing. To date, conical rotors are the ones that require small amounts of material, typically <2 mL. Others, such as cylinders and discs, may require as much as 500 mL. A special chamber used with the cylinder can reduce the sample volume to 20 mL. The bottom line is that tapered spindles are limited to very small sample sizes. This may be a good choice, provided the sample is homogeneous when testing such a small amount of material.

The test method also needs to be considered when performing viscosity measurements. QC labs typically perform single-point testing, which involves rotating the spindle at a specified speed for a specified time interval and then recording the viscosity value. R&D labs often wish to characterize materials and therefore need to rotate the spindle at multiple speeds. This shear action on the sample can be related to the forces exerted on the material during handling (mixing, pumping, flowing in pipes) or operator use (rubbing, spreading or swallowing). The tapered spindle provides a wide range of shear rates per spindle revolution. Therefore, it is very popular in R&D laboratories. QC laboratories performing two-point testing, where the specified shear rates are widely apart (for example, 10 sec -1 and 1000 sec -1 ), make tapered spindles the preferred choice.

The viscosity of most materials is temperature dependent. The measured viscosity generally decreases with increasing temperature. QC labs typically have a controlled temperature specification for acceptance of production samples. Commonly used control values in industry are 20°C and 25°C; medical and pharmaceutical industries may require body temperature or 37.6°C. If the sample size is small, the time required to bring the material to the specified temperature is minimized. The use of tapered spindles can be used to great advantage. It is worth mentioning that the cone shaft should also be tempered at the same temperature as the sample material before taking viscosity measurements.

The amount of sample required for viscosity testing is an important consideration for QC laboratories. Given the heavy workload that grows every year, time is precious. A cycle time comparison for viscosity measurements with each spindle type needs to include:

Sample preparation for placing the sample in the instrument

When to Run the Viscosity Test

Instrument cleaning after testing.

Again, the tapered spindle is the winner due to the small sample size. The sample cups also need to be cleaned, but this is much easier than dealing with all the surface area in a 500 mL beaker. The cone and plate viscometer has compact components, as shown in Figure 3. A tapered spindle is attached to a shaft in a long tube extending down from the head of the instrument. The sample cup is attached to the bottom of the test tube. The port on the tube is connected to a circulating Water Bath to control the temperature of the sample. The system (instrument plus tub) costs between $5,000 and $10,000, depending on the model. Although more expensive than standard viscometers with cylindrical or disc spindles, the time savings when running viscosity tests is more than justification for choosing cone and plate.

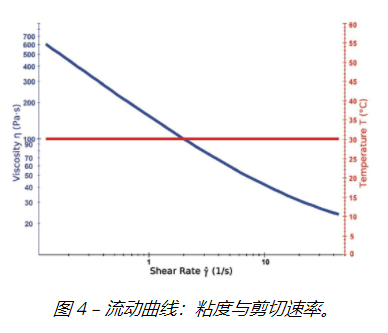

Samples sent to the author's laboratory for customer evaluation are typically evaluated using the cone and plate method. This viscometer type was chosen for the same reasons as above. The total time required to generate a flow curve showing viscosity versus shear rate is just a few minutes (see Figure 4). Furthermore, the range of shear rates is wide enough to exhibit shear-thinning behavior (decrease in viscosity with increasing shear rate) of pseudoplastic materials. If the customer requests multiple temperatures, it will obviously take longer because the circulating bath needs to be equilibrated at each temperature. Additionally, the gap between the conical rotor and the sample plate needs to be adjusted to account for thermal expansion or contraction of the rotor/plate (usually required when the temperature difference between the set points is greater than 5 °C).

in conclusion

Due to the many advantages mentioned above, cone and plate viscometers are becoming more and more popular throughout the industry. They have long been the instrument of choice for R&D labs. Now, people are noticing productivity gains in QC testing, and word is that high-volume workloads are better handled with cones and plates.