Testing the properties of products such as paints, varnishes, cosmetics or glues; is an important part of their development. In order to test them, consistent and repeatability samples need to be made for fair, accurate and comparable testing. This is where film and bar Spreaders come in.

Whether used manually or with the Automatic Film Applicator, the film and bar Spreader are designed to help you make reproducible films with defined Film thicknesses.

This article will show how each filmmaker works and the types of applications they are designed for.

Baker Film Applicator

1. Fixed Film Applicators

Baker films start with commonly used multifunctional films, made of hardened stainless steel, each with four precisely specified coated Film thickness dimensions.

The film dispenser is placed on a flat substrate with the film thickness value you wish to create close to the substrate. Then spread the product you want to make the sample film evenly in front of the applicator. Try to avoid placing the product in front of the applicator's feet as this can cause it to become uneven and affect the conformity of the film.

The filmmaker then moves over the substrate at a steady speed, scraping the sample through a precisely designed gap, resulting in a set film thickness. Remember that the film thickness defined by the filmmaker is the thickness of wet film, not the thickness of dry film. While there are many different filmmaker designs, they basically all work this way.

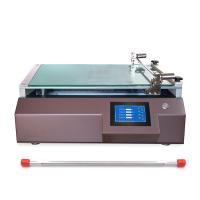

It is important to note that human error can lead to inconsistencies between films when preparing films manually. Differences in the smoothness of the finished film, the speed at which the applicator is moved, or the downward force applied when moving the film can all affect the resulting film. This is where the Experimental Automatic Film Applicator comes in to eliminate human error.

2. Adjustable Film Applicators

In addition to the standard Baker Film Applicator, the adjustable Baker Film Applicator, as the name suggests, has adjustable legs so you can set specific clearance sizes. Loosen the hex screws on the base with the provided wrench and you can individually set the film thickness clearance for each foot. So, by setting both feet to the same Film thickness, you can produce a uniform film, or you can have one Film thickness higher than the other, resulting in a film wedge with a gradual change in Film thickness, often used to test the product coverage or hiding power. Both adjustable and non-adjustable Baker Film Applicators are available in a variety of widths and coated Film thicknesses.

3. Bird-type Film Applicator

Single-sided and 4-sided film is another universal film can provide a single film thickness or four different film thickness.

Bird-type single-sided and 4-sided films come in a variety of Film thicknesses and widths, are easy to clean, and have a flat-sided prismatic body, as opposed to the circular design of Baker films. However, these films work exactly the same way - simply film your product evenly in front of the Film thickness gap, again avoiding the foot, and then complete the manual or automatic film.

Wire Film Applicator

The bar Spreader works slightly differently than the film machine. Consists of a cylindrical bar wound with stainless steel wire of specified diameter; the product you want to make the sample film is placed in front of the Bar Coater, and when the Spreader moves on the substrate (again this can be done manually or automatically), the product flows between turns of the stainless steel wire.

This simulates how the coating is applied when using a paint brush. The product should then be sedimentation or flattened to the thickness of wet film defined by the Bar Coater. Therefore, this method is only suitable for products with high levelling characteristics and low viscosity. Best for materials with a viscosity range of 1-1000 cpoise, limited to outflow after coating.

When using a wire rod Spreader to prepare films, it is important to use a rubber pad (also known as a Drawdown Plate) because its properties help the product flow out and levelling after completion of the stretch, thereby improving the repeatability.

Frame film

Precision designed from hardened stainless steel to provide four Film thicknesses in one specification. Simply swirl/spin the applicator so that the Film thickness of your choice is facing away from the substrate and away from the direction in which you will move the applicator, fill the reservoir with your product, and finish the application. Some 4-sided gap films have two containers, ideal for comparing two coats at the same time, or preparing samples for abrasion Testers and washability Testers. When used manually, it helps you achieve perfect linear stretching, ensuring that the coating strips remain separated.

Cube film

Available as a single cube or five strips, the Cube films allow you to precisely apply 12 mm wide film strips. Each Cube film is equipped with a set of 30-1000 μm Film thickness meters for adjusting film thickness. Simply insert a gauge of the desired Film thickness and place

Fix the blade on it, tighten the blade setting screws, remove the Thickness Gauge, and film the product into the reservoir. The 5 cube strip allows you to quickly and easily create five identical film strips of the same Film thickness, or you can place individual cubes of different Film thicknesses of your choice to create a sample where Film thicknesses can be quickly compared.