Spin coating is one of the industry methods for depositing thin films of materials onto functional substrates. Thin films have no chemical limitations; they are simply layers of any material ranging in thickness from a few micrometers (μm) to a single nanometer (nm).

film background

Thin films are commonly used as electronic, optical, protective and even decorative coatings. In fact, engineers trace the origins of film deposition to decorative gold leaf coatings on ornaments as early as 2600 BC. The method of sinking an active thin gold coating is called gold plating. The term includes even the most basic technique of simply hammering gold leaf onto a surface with an intermediate layer of adhesive. While that may sound crude by today's standards—thin films can be chemically synthesized under ultrahigh vacuum (UHV) conditions—some common thin film deposition methods still rely on applying force to coat the substrate: spin coating.

What is Spin Coating?

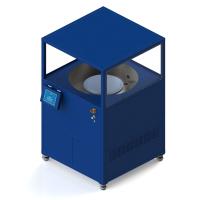

Spin coating is a method that uses centrifugal force as the deposition method to produce uniform thin films. In a typical process, a uniformly planar substrate (i.e., an electronics wafer) is held on a spindle, and a liquid precursor/nanoparticle solution is dispensed by a syringe into the center of the workpiece. The substrate is then accelerated centripetally, which causes the liquid to spread across the surface by centrifugal force. Excess material is flung off the edge of the rotating substrate, leaving a uniform film on the surface.

How does spin coating work?

The process works by carefully controlling the speed in relation to the various material properties of the solution. Viscosity is the first of these properties because it determines the resistance to uniform flow, which cannot be overemphasized for its importance in achieving a uniform surface finish. This is followed by spin coating over a wide range of speeds, from as low as 500 revolutions per minute (rpm) to as high as 12,000 rpm - depending on the viscosity of the solution.

However, viscosity is not a material property of interest in spin coating. Surface tension can also affect the flow characteristics of a solution, while percent solids can affect the film thickness required to achieve specific end-use properties (i.e., electrical mobility). Subsequent spin coating is performed with full knowledge of the relevant material properties, with a large number of adjustable parameters to suit different properties (flow, viscosity, wetting, etc.).

Spin coating can be performed using static or dynamic starts, each of which can be programmed for user-defined acceleration ramps and various spin speeds. Allowing time for fume extraction and drying is also important, as poor ventilation can lead to optical defects and inhomogeneities. For example: A swirl pattern may indicate that the exhaust rate is too high for a solution that takes longer to dry. There is no one-size-fits-all solution when it comes to spin coating, each process requires a holistic approach to the substrate and coating solution in question.