Spin coating is a procedure used to deposit uniform thin films onto flat substrates. Typically a small amount of coating material is applied to the center of the substrate, which is either rotated at low speed or not at all. The substrate is then spun at high speed to spread the coating material by centrifugal force. The machine used for spin coating is called a Spin Coater, also called a glue spreader.

Before applying your first film, a successful result requires your attention to the following:

• Environmental conditions, including temperature, humidity, particulate matter in the air, etc.

• The quality of your consumables – are your chemistries fresh?

• Cleanliness of substrate and equipment. Starting with a contaminated substrate can ruin your process before it even begins

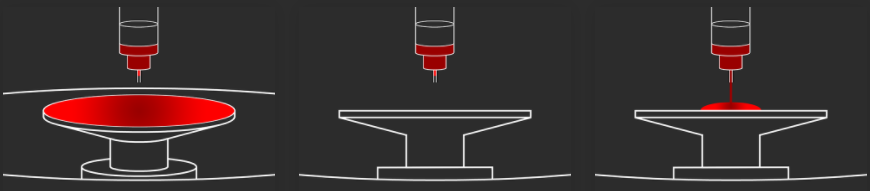

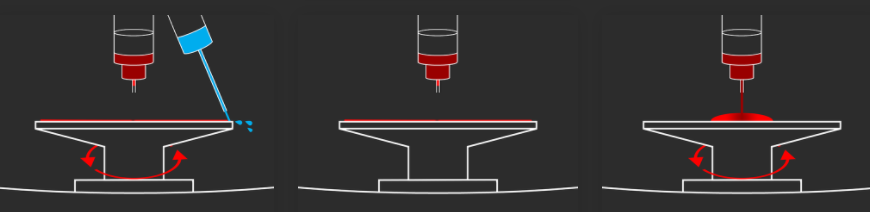

1. Properly centered substrate Accurate centering of the substrate on the Spin Coater results in a consistent coating. Irregular shapes need to be centered on the eye. Square and rectangular substrates benefit from the drop-in chuck, which automatically centers the substrate and reduces edge build-up during spin coating. | 2. Static dispensing Most people start with spin coating using the static dispensing method. This is an easy way to start spin coating and requires you to dispense chemicals onto a fixed substrate. | 3. Inject your coating sample Using a pipette or syringe through the hole in the Spin Coater lid, dispense a steady stream of chemicals into the center of the substrate. Generally, material should be dispensed until it covers 50% of the diameter of the substrate. |

4. Start spinning Once the correct amount of material has been dispensed, the coating procedure begins. Laurell coaters are fully programmable at every step of the spin coating recipe for increased speed and acceleration. | 5. Diffusion Your Spin Coater should be programmed to allow intermediate steps to accelerate the substrate to a moderate speed and allow the chemicals to spread smoothly across the surface. | 6. Excess material is discarded When the material reaches the edge of the substrate, a further acceleration step casts excess material from the wafer. The process chamber of a Laurell Spin Coater is designed to prevent excess material from splashing back onto the substrate. |

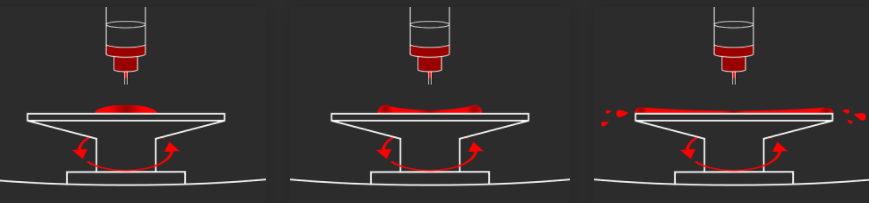

7. Accelerate to final rotation speed This last step requires your Spin Coater to be rapidly accelerated to the final spin speed required to produce a coating of the correct thickness. | 8. Solvent evaporation At the final spin speed, the solvent will evaporate from the coating. Controlling the exhaust volume on the Spin Coater will allow you to adjust the concentration of solvent vapor in the process chamber. | 9. Edge glue The spin-coating process leaves a buildup of material at the edge of the substrate. |

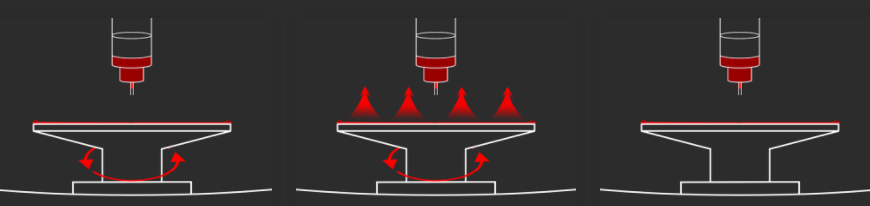

10. Remove edge glue Edge bead removal on round wafers is recommended immediately after the coating process in a Spin Coater. After the coating has cured, a stream of solvent is directed to the edge of the substrate while rotating at low speed. The wafer continues to spin to allow any remaining solvent to dry. | 11. Finished coating After removing the edge glue, the coating process is complete. | 12. Dynamic allocation Dynamic allocation is a better alternative to static allocation. This requires you to start the Spin Coater before dispensing the material onto the spinning substrate. |

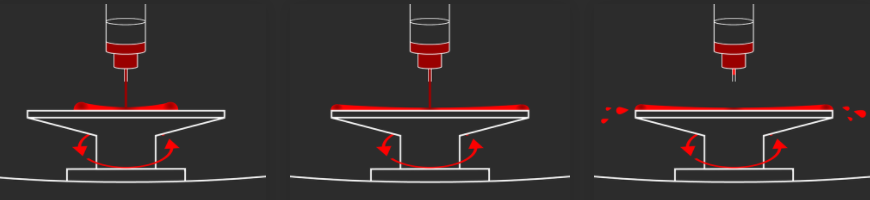

13. Distribute while rotating The chemicals are dispensed while the Spin Coater spins the substrate at approximately 500RPM. The smooth flow of material distributes it evenly for a better coating. | 14. Dispensing glue to the edge of the substrate Stop dispensing your chemical when the puddle reaches the edge of the substrate . Better results are obtained if the Spin Coater is programmed to move to the next step when the initial dispense is complete. | 15. Accelerate into the degumming step When the chemicals reach the edge, the wafer should be accelerated to remove excess material. From this point on, the process is the same as for static allocation. Dynamic dispensing produces a more consistent coating and helps reduce chemical usage. Reducing the amount of material used will save money and time spent cleaning your Laurell coater. |