The Spin Coater glue homogenizer needs careful maintenance during daily use. Of course, it is inevitable to encounter some faults. Here are a few common faults and how to maintain them, including substrate pollution, particle pollution, and chemical pollution.

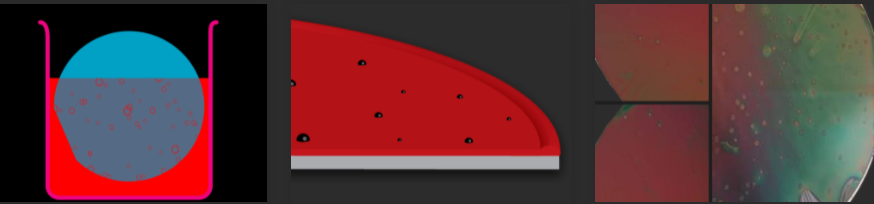

1. The substrate is contaminated A contaminated substrate may not completely ruin your coating, but why would you spend time and effort on a spin coating process that is flawed from the start? A complete cleaning process should address all forms of contamination. | 2. Particle pollution After cleaning, particle contamination may occur during spin coating. | 3. Chemical pollution Simple observation cannot always discern chemical contamination remaining on the wafer that interferes with the spin-coating process, but the results are obvious. The image above shows voids in the coating caused by invisible contamination spots. |

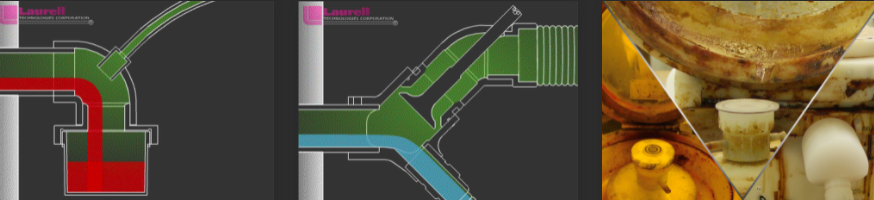

Exhaust - Spin Coating Venting is an often overlooked part of spinning processing operations. For simple spin-coating procedures, the exhaust should be sufficient to draw any chemical vapors away from the operator. | Exhaust - Etching, Developing and Cleaning Proper exhaust levels are even more important when doing water treatment in a Laurell EDC system. All possible inputs, chemicals, DI water for flushing, gases for clearing wet paths and drying substrates need to be balanced with adequate exhaust. This prevents an overpressured environment in the process chamber and removes excess moisture quickly. | Cleaning Your Coater Spin Coater If you want better spin coating results, your Spin Coater should be spotless. Your process should be optimized to use the minimum amount of chemicals and the Spin Coater should be cleaned at the end of each session. |