In general, dynamic allocation is preferred as it is a more controlled process that provides better substrate-to-substrate variation. This is because there is less time for the solvent to evaporate before starting to spin, and ramp speed and dispense time are less critical (as long as the substrate is allowed time to reach the desired rotational speed). Dynamic dispense also generally uses less ink, although this does depend on the wetting characteristics of the surface.

The disadvantage of dynamic dispensing is that it becomes increasingly difficult to obtain complete substrate coverage when using low spin speeds below 1000 rpm or very viscous solutions. This is because the centripetal force is not strong enough to pull the liquid across the surface, and the lower spin speed also means that there is an increased chance of dispensing the ink before the substrate completes a full spin (at 600rpm, the substrate spins every 0.1 sec, which is comparable to a pipette rapid decline).

Dynamic Dispensing Spin Coating Technology

For most spin coatings above 1000rpm, dynamic dispensing should be used as standard unless there are any special circumstances or difficulties.

A pipette is typically used to dispense a known volume of solution at a time - typically 20µl for most common substrates/inks on standard size (20 x 15mm) substrates and 100µl for 50 x 50mm substrates. However, if wetting is an issue, adding volume may help.

In order to obtain a high quality and consistent film, the following points need to be observed:

The substrate should have reached the desired rotational speed (usually only a few seconds) before dispensing occurs.

Ink should be deposited as close to the center of the substrate as possible, otherwise gaps may appear in the middle.

Ink should be deposited in one quick and smooth motion.

Ink should be deposited in one drop and only one drop to prevent multiple coats.

There should not be any air bubbles blown from the pipette onto the surface.

Pipette tips should not touch the spinning substrate.

It is also worth noting that for spin coating, better results can be obtained by using the pipette in a non-standard manner. Typically, when pipetting solutions, the pipette will use a second stop to draw extra solution into the tip and then discard it. However, this causes more water droplets or air bubbles to be projected onto the surface. Therefore, it is recommended to only use the pipette to the first station when spin coating.

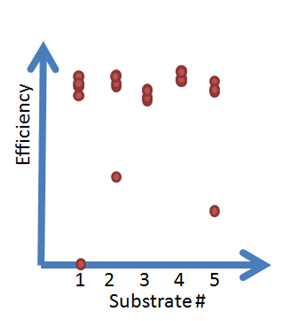

The above points will help to provide better film uniformity for specific substrates. However, in a research setting, especially new users (but also applicable to experienced users) often find that the variation between substrates is often greater than the variation between substrates. While this is usually a small effect, it can be an important consideration, especially for statistical results.

Pictured is an example of statistics for a solar cell with multiple pixels per substrate in a typical lab environment. In a research environment, there are usually a few bad pixels, but typical performance differences between pixels may be small compared to differences between substrates.

Therefore, in order to obtain better consistency between substrates, there is a critical "practical factor". This means that once an action (or combination of actions) has been performed multiple times, it is committed to "muscle memory", meaning it is done automatically with little or no conscious effort. This generally means dispensing occurs more consistently and accurately, which has implications for film quality.

Static dispensing and spin coating technology

It becomes increasingly difficult to obtain high quality films as the spin speed is reduced below 1000 rpm or with very viscous solutions. Therefore, if possible, it is generally recommended to reformulate the ink (increase concentration or change solvent) to spin at a speed higher than this. However, there are many situations where it is not desirable or possible in nanotechnology. For example, better crystallization occurs at low speeds, while some materials are not soluble enough to achieve the desired thickness at 1000rpm.

Dynamic dispensing can be achieved all the way down to around 500rpm, but it becomes more difficult to get complete substrate coverage, so more ink is required (using 50µl dots instead of 20µl will help with coverage, but at more Multiple material waste charges). Therefore, it can be considered that the cut-off point is around 700 rpm, below which the static dispensing spin-coating method starts to provide better film quality.

When using static dispensing, it is common to coat the entire substrate (or at least all active parts of the substrate) before starting spin coating. However, this in itself can cause several problems. The first is that unless the substrate surface has exceptionally good wetting for the ink (ie the ink likes to spread out across the surface), it will usually be necessary to use a pipette tip to "pull" the ink across the surface. However, it is of course very important that the pipette tip never touch the substrate surface in the active area as this will alter the surface properties and/or damage any other layers present.

Ink can be moved around the surface without touching the surface by carefully placing the pipette tip close to the surface so that it touches the edge of the ink drop. Alternatively, if the edge of the substrate is not critical, the pipette tip can be moved around the edge of the substrate to pull the meniscus. A third option is to add more and more ink until the substrate is completely covered, but this is generally not recommended as up to a milliliter of solution may be required in extreme cases for this to occur.

In conclusion, in some cases it is necessary to statically dispense viscous solutions and ensure that they are applied directly to the edge of the substrate. In this case, due to the viscosity and relatively low wettability of the ink, it is difficult to use a pipette tip to pull the meniscus to the edge without touching it.

Instead, use a different spin-coating method in which the pipette tip is held at a 45-degree angle to the substrate and moved along the far edge of the substrate.

However, one of the main problems with static dispensing is that the solvent in the ink has some time to evaporate before the spin coating process begins. For low vapor pressure solvents such as water this is not a big deal, but for high vapor pressure solvents such as chloroform (about 10 times higher than water) it can be critical, depositing the solution and starting spinning The time in between can have a great effect on both film thickness and film quality.

This is the main reason why static dispensing reduces substrate-to-substrate film uniformity and dynamic dispensing is recommended if possible.