comet

These typically occur when relatively large solid particles impede the normal flow pattern of the solution over the spinning wafer. Flow is generally smooth and radial except during "spin" (radial velocity gradients are governed by applicable force balance and viscosity constraints. The presence of comets can be reduced by working in a cleaner environment and filtering the coating or Eliminate solutions as part of the distribution process.

stripe

Streaks are radially oriented lines of thickness variation in a coated film. Typically they are very smoothly varying thickness variations with a pitch or periodicity in the range of 50-200 microns or so. Their orientation corresponds to the direction of the main fluid flow. Their appearance is thought to be due to surface tension effects driven by evaporation. Early evaporation of light solvents can lead to enrichment of water and/or other less volatile substances in the surface layer. If the surface tension of this layer is greater than that of the starting solution (and still exists at a deeper level), there is instability, where the higher surface tension actually draws the material in at regular intervals, while the space in between is more Able to evaporate, and surface relief develops. This is largely due to the Marangoni effect, which governs the development of structure in the wine's drainage pattern on the side of the glass: the ethanol evaporates first, leaving an ethanol-depleted layer of wine that collects in creeks and drains along the glass wall.

Evaporation-driven surface tension effects can create streaks by:

The evaporation process leaves the top layer with a different composition and therefore a different surface tension. The top surface can then become unstable against "long-wavelength" perturbations, which in turn become unstable. The exact conditions governing what is stable and what is unstable remains unknown. Our preliminary model is that you would expect the evaporation process to drive the local surface tension to lower values, which would tend to stabilize the system. A number of sol-gel and polymer coating systems are currently being tested.

Chuck mark

These patterns can be created by thermal "communication" between a solution on top of the wafer and a metal vacuum chuck on the backside of the wafer. Therefore, the thermal conductivity of the substrate material and the thermal driving force (mainly evaporative cooling, but possibly also due to temperature differences between the solution and the substrate and chuck) are very important. The right image has a single-layer sol-gel derived coating on a glass substrate. Silicon wafers generally have less thickness variation than glass or plastic due to their higher thermal conductivity.

environmental sensitivity

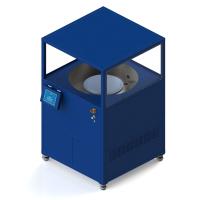

When coatings are made in the surrounding environment, the surrounding environment may have an impact on the quality of the coating. A key variable is the humidity of the surrounding air. For many solutions, water plays an important role in the chemistry of the solution itself, so different coating qualities may result when different amounts of water are present in the environment. This can manifest as rough coating, micro-cracks in the coating as it dries further, exaggerated streaks forming in the coating, etc. Obviously, the importance of close control of the environment surrounding the Spin Coater is self-evident.

Wafer Edge Effect

The edge of the substrate is always an area of concern. If better uniformity can be maintained at the edges, more area can be used for device fabrication. Edges are problematic for several reasons. First, surface tension effects make it difficult for radially outwardly flowing solutions to detach from the wafer. Thus, a small "bead" of liquid can remain attached around the entire perimeter and create a thicker coating in this edge area. Also, if the substrates are not perfectly round, especially if they are square or rectangular, the airflow over the protrusions (corners) will be disturbed. While the flow may still be laminar, it will have a different flow history, often resulting in uneven coating thickness in these corner areas.