After the powder coating is sprayed, it enters the baking furnace to melt, level, cross-link and solidify the powder coating to form a film. For thermoplastic powder coatings, it only needs to be melted and leveled to form a film; for thermosetting powder coatings, it needs to be melted and leveled while being cross-linked and drawn into a film.

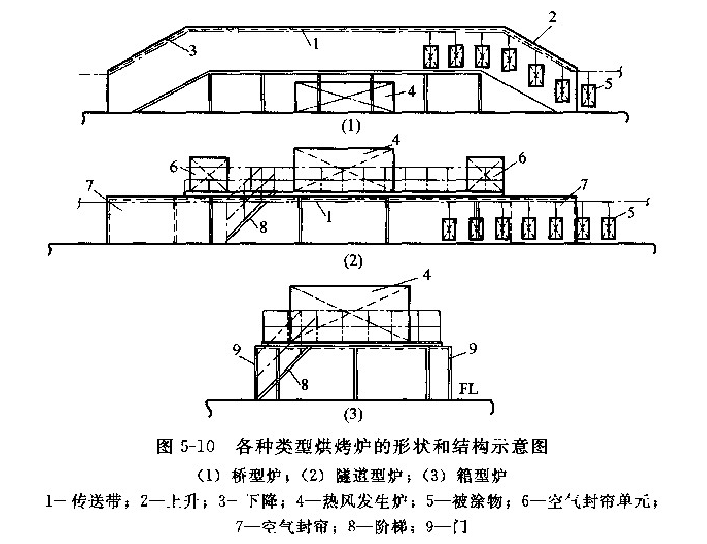

Baking oven is one of the equipment required in powder coating. From the configuration of the oven, there are bridge type, tunnel type and Cabinet-type, various types of baking force, shape and structure. Bridge-type and tunnel-type ovens are suitable for automatic spraying production lines; noodle box-type ovens are suitable for sub-discontinuous production.

In the bridge type furnace, due to the structural relationship of the furnace, it is not easy to form convection between the hot air in the furnace and the cold air outside the furnace. When the coated object enters the baking furnace, the heat loss in the furnace is small, and the furnace temperature Good insulation effect. The disadvantage of this kind of baking oven is that the furnace body takes up a lot of space, and when the shape of the object to be coated is complex, and the distance between the hangers is not suitable, it is easy to collide between the objects to be coated when the hangers go uphill or downhill. The adhesion of the coating film can easily affect the quality of the coating product.

In the tunnel-type oven, the oven occupies less space than the bridge-type oven, and the product quality will not be affected by the complex shape of the object to be coated and the same distance from the hanger as the bridge-type oven. The disadvantage of this kind of oven is that the hot air in the oven and the cold air outside the oven are easy to convect, and the heat loss in the oven is large. Therefore, in order to prevent heat loss, an air curtain is installed at the inlet of the oven to be coated.

The structure of the box-type furnace is simple, and the temperature distribution in the furnace is relatively uniform; the disadvantage is that it is not suitable for continuous automatic production.

The heating methods of the oven include electric heating, combustible gas heating, oil heating and coal heating. In the electric heating mode, there are electric furnace wire heating, infrared plate heating, infrared tube heating, infrared lamp heating and induction heating. The gases used in combustible gas heating methods include coal gas, natural gas and propane gas. The oil used in the oil heating method includes kerosene, diesel oil and heavy oil. Among the heating methods of these combustion gases and oils, they can be divided into direct heating methods and indirect heating methods through heat exchange through heat exchangers. Generally, direct heating methods are used for burning coal gas, natural gas and propane gas, while burning kerosene, Collecting oil and heavy oil are heated indirectly.

In the hot blast stove with electric heating method, in order to make the temperature distribution in the furnace uniform, the air in the baking furnace generally needs to be circulated by the blower. In contrast, the temperature distribution in each part of the furnace is relatively uniform.

In the electric heating infrared furnace, part of its energy is heat energy, and the other part is radiation energy. According to the conversion efficiency of electric energy, the proportion of the two is different. For the infrared baking furnace that combines thermal energy and radiation energy, because the coated object of powder coating is subjected to infrared radiation, the object to be coated starts to heat up from the inside, and the powder coating layer is heated from the outside by the action of heat energy, so the coating The temperature rise rate of the film layer is fast; the disadvantage is that the temperature distribution in the baking furnace is uniform; the farther the distance from the heat source is, the lower the temperature is. There is also a significant difference in the baking curing effect, and the coating film is not uniformly cured. Therefore, this type of baking furnace is only applicable to the baking cycle of the flat plate shape or the simple circle-shaped coated object that can rotate in the baking furnace, and does not fit the baking and curing of the complicated shape coated object.

Gas-burning, oil-burning and coal-burning ovens are generally hot Air Ovens. The advantage of hot Air Ovens is that the temperature distribution in the oven is relatively uniform and the temperature is easy to control. It is suitable for baking coated objects of various shapes and sizes. Curing; the disadvantage is that the heat transfer of the coated object gradually heats up from the surface to the inside, and the temperature of the coated object rises slowly. In addition, the combustion residue in the hot blast stove or the dust in the air can easily contaminate the coating film.

Although the cost of the coal-fired hot blast furnace is relatively low, the temperature control of the baking furnace is not as convenient as electric heating, gas heating and oil heating. Next, when other energy sources are in short supply, there are also baking ovens that use this heat source.

In actual production, what kind of heat source to use depends mainly on the local energy situation and price. Electric heating can be used in places with rich power resources and cheap prices; if oil products and natural gas resources are relatively rich, oil heating and combustible gas heating can be used. Judging from the current domestic use situation, in coastal areas, burning oil and combustible gas is more than electricity consumption, especially large-scale automatic coating lines use more oil-burning hot air stoves.