A peel test is a slow vertical (usually 90 or 180 degree) pull applied to a work sample and involves a "peel-like" motion.

For the peel test, a tweezer puller is required; once the cartridge is installed, you will be able to select "Peel Test" as a test option. This test is essentially the same as the standard tweezer pull test, but with the addition of XY movement in a selected direction while the tool applies an upward load.

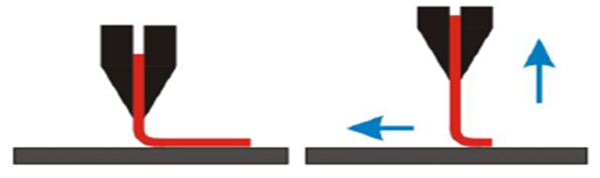

This figure shows a standard peel test with the jaws of the tweezers pressed against the test object.

Then the Z axis moves up, and the XY stage moves in the specified direction.

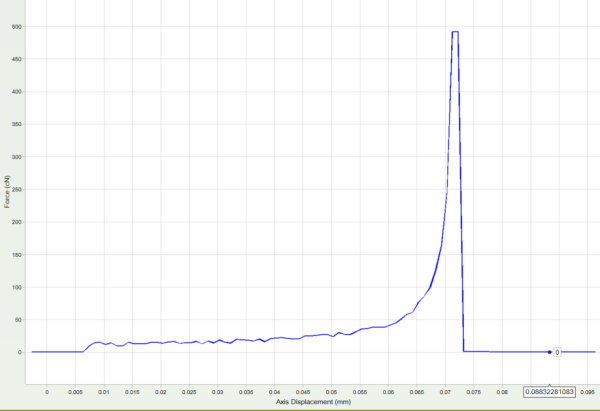

Once a peel test has been performed and completed, a graph of the results is available. The second graph shows the force-displacement results of a sample peel test performed on a Dage4000Plus material testing system.

Basically anything that needs to have its bond strength measured will be subjected to a peel test. Examples can include:

Adhesive testing; tapes, epoxies, etc.

Solar panel testing; testing interconnects, different types of laminates, etc...

NOTE: To perform a peel test you will need a tweezer pull box and a motorized XY stage.