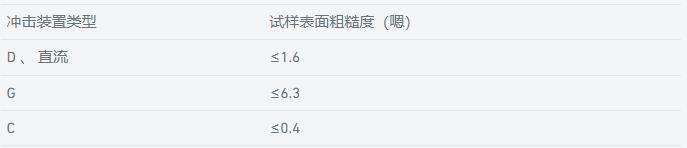

1. Requirements for the surface of the sample

The test surface should have metallic luster, no scale and other dirt, and the surface roughness should meet the following requirements:

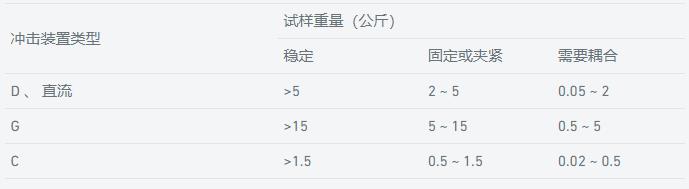

2. Sample weight requirements

Specimens need to be of sufficient mass and stiffness to ensure no displacement or rebound during reconstruction. Quality should meet the following requirements:

3. Sample thickness requirements

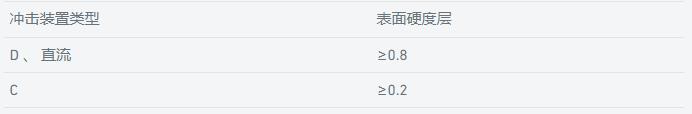

The sample should have sufficient thickness, and the minimum thickness should meet the following requirements:

4. There is a hardened layer on the surface of the sample, and the depth of the hardened layer should meet the following requirements:

5. For concave, convex, cylindrical and spherical samples, the surface curvature radius should meet the following requirements:

For specimens with curved surfaces, appropriate support rings should be used to ensure that the position deviation of the impact head is within 0.5mm during impact.

6. The sample should not be magnetic.

7. The distance between each measurement point should be greater than 3~4mm, and the test cannot be repeated at the same point, otherwise it will cause a large error. At the same time, the service life of the sensor will be shortened.