What is gloss?

According to the UNE-EN ISO 2813 standard, "gloss" is the optical property of a surface characterized by its ability to reflect specularly reflected light. '

Gloss is an important property of objects and surfaces relevant to our visual perception. Like color, gloss is an essential parameter for evaluating the appearance of a product surface. Therefore, gloss measurement is a common activity in quality control of production processes.

The perception of gloss is related to the finish of an object, including texture, roughness, etc. Smooth and polished surfaces create a more shiny feel than rough surfaces.

The glossiness of an object, product or surface can determine consumer acceptance or approval, or conversely, rejection, of said product or finish. Therefore, it is very important to perform gloss evaluation objectively and quantitatively using a gloss meter. The use of gloss meters is a common pattern in paint, varnish, plastic, automotive, etc. companies.

How to measure the glossiness of an object?

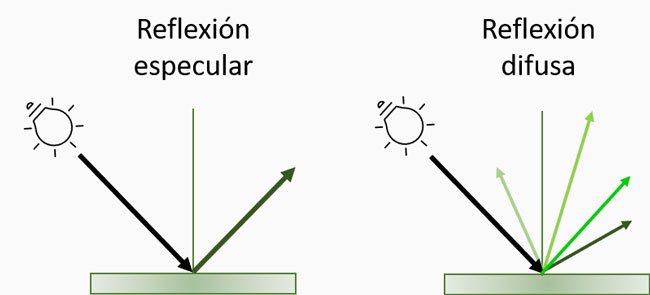

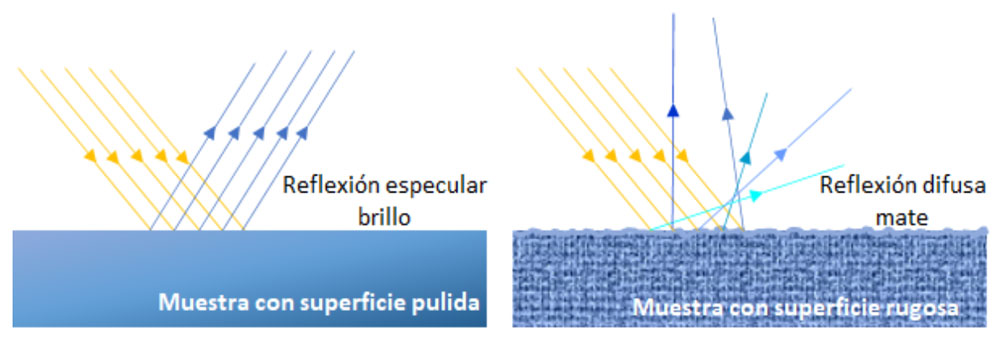

Diffuse and specular reflections occur on surfaces when light hits them. In diffuse reflection, light rays are emitted in different directions, while in specular reflection, light rays are reflected in the same direction or at the same angle of incidence.

Diffuse is responsible for the color of the object, while specular is responsible for the glossy effect.

In materials with rough and non-smooth surfaces or finishes, the amount of diffuse light will be greater than direct light or specular light, resulting in matte, low gloss or semi-gloss surfaces.

While in polished and smooth finishes the proportion of direct light reflection is greater because the light is reflected directly at the same angle of incidence, in which case we would have a high gloss surface or finish.

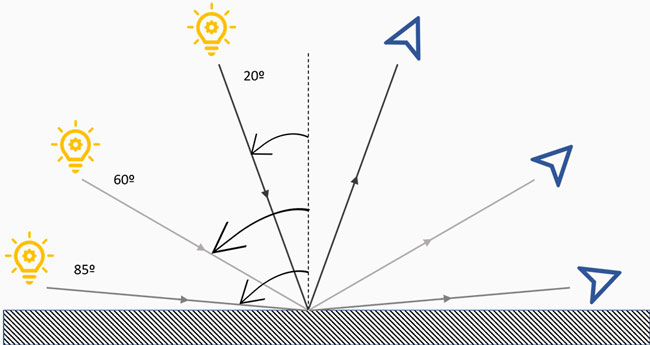

In addition to surface finish, there are other factors that can affect gloss measurement. The angle of incidence, and therefore the angle of observation, is one of them. If the same surface or object is illuminated at an angle of 20º (relative to the surface normal), the same surface or object will not appear as shiny as at 85º.

Therefore, the recommendations for choosing the best geometry for gloss measurement are as follows:

High-gloss surface: 20º viewing angle

Semi-gloss finish: 60º viewing angle

Matt finish or low gloss: 85º viewing angle

What is a Gloss Meter?

The physical principle of gloss measurement is to measure the specular reflection from a surface. For this, we use a gloss meter, which is an optical device that illuminates an object, sample or surface and evaluates the reflected light.

Gloss meters are reflective measurement devices that measure the specular reflectance of a surface or product and return the measurement in gloss units: GU (Gloss Units). Gloss meters relate the visual perception of gloss to gloss units.

This GU scale is based on the specular reflectance at given angles (20º, 60º, and 85º) of a black glass material with a nominal refractive index of 1.567 when illuminated with 587.6nm monochromatic light. Reflexes under these conditions were assigned a value of 100GU.

It is important to note that the gloss unit scale, while based on the amount of light reflected, does not refer to a percentage, nor can it be expressed as % reflectance.

How does a gloss meter work?

As mentioned earlier, a gloss meter or reflectometer measures the light reflected from a specular surface, usually at angles of 20º, 60º and 85º.

There are a wide variety of gloss meters on the market today, some configured to measure the three geometries mentioned above, while others have simpler optical designs that measure gloss only at the 60º geometry.

Typically, a gloss meter comes with a reference gloss standard. This standard is usually high-gloss polished black glass. This standard serves as a reference when the equipment is in operation and adjusts subsequent measurements made with the equipment.

These tuning standards express their values in gloss units and are available for different measurement geometries. In order to use a gloss meter properly, it is important that this gloss standard is kept in perfect condition and that the standard fluid is free of dust, scratches, fingerprints, etc. while adjustments are being made.

Another aspect to consider when using a gloss meter is the measurement direction, which is the direction of incoming light. In some models of gloss meters, a pictogram is included indicating the direction of measurement.

Gloss Meter Calibration

Like other measuring equipment, gloss meters require regular calibration to ensure the quality and traceability of measurements to internationally recognized reference standards. Furthermore, calibration is required for all measurement geometries and different gloss values used.

Calibration frequency, such as annually, needs to be determined by the user based on usage and calibration history.

What is an accredited calibration laboratory?

An accredited laboratory is a laboratory recognized by a national accreditation body for its work in accordance with the UNE-EN ISO/IEC 17025:2017 standard, which includes general requirements for the competence of testing and calibration laboratories. An accredited laboratory is one that can provide the necessary confidence and assurance in its calibration and test results.

What is a calibration certificate?

A calibration certificate gives the correctness of the device and its uncertainty. This correction is something users need to consider in their daily measurements.