The cupping performance of the coating film can be determined according to the method in the national standard "Cupping test of paints and varnishes" (GB/T9753-88). This standard is equivalent to the international standard ISO 1520-1973 «Cup test for paints and varnishes». This standard specifies the evaluation of the performance of the coatings of paints, varnishes and related products against cracking or separation from the metal substrate after gradually deforming them under standard conditions (recommended instrument: cupping Tester). The test method specified in this standard can be tested according to the specified indentation depth to evaluate whether it is qualified. The indentation depth can also be gradually increased to determine the minimum depth at which the coating just cracks or begins to detach from the substrate.

(1) Equipment

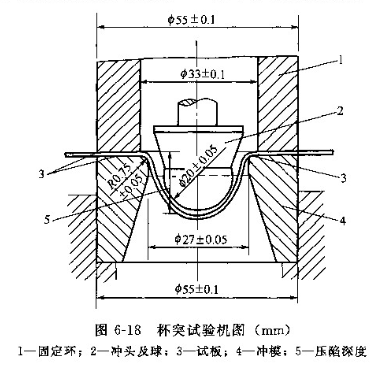

① The cupping testing machine shall comply with the design and dimensions shown in Figure 6-18.

② Test panel Unless otherwise specified, the test panel should be a polished steel plate and meet the requirements of GB/T 9271. The test plate is square and the thickness is 0.30~1.25mm. The width and length are not less than 70rnm.

(2) Test procedure

①The test should be carried out in an environment with a temperature of 23°C±2°C and a relative humidity of 5o%±5% (except for special regulations).

②Fix the test plate between the fixed ring and the die, with the coating facing the die. When the punch is at zero position, the top is in contact with the test plate. Adjust the test plate so that the distance between the center drawing line of the i-head and the test plate is not less than 35mm from each side of the plate.

③ Push the hemispherical tip of the punch to the test plate at a constant speed of 0.2 nm-10.1 mm per second until it reaches the specified depth, which is the distance the punch has moved from zero. During the test, the punch should be prevented from bending, and the deviation between the center of the top of the spherical surface and the axis of the chess in i should not be greater than 0.1mm.

④ With corrected normal eyesight or a 10 times magnifying glass upon approval, check whether the layer of the test panel is cracked or separated from the substrate. The above procedures should be carried out on a separate test panel. If the results are different, additional tests should be performed until the results of the two test panels are consistent; otherwise, the test results are invalid if cracks appear on the substrate.