Slot die coaters are designed and manufactured based on providing uniform solution delivery to a given surface. This single, simplified requirement can be difficult to manage when transitioning from uniformly coating small areas (a few square millimeters) to coating larger areas (multiple square meters). To achieve this, the slot die coater is broken down into several specially designed subsystems.

There are four different subsystems:

Metering system controls the flow rate of solution into the system

The distribution system ensures that the solution is evenly distributed across the width of the coating

Head positioning system maintains the position of the head relative to the substrate

The substrate movement system determines how the substrate passes through the slot die head

The solution distribution is controlled by the slot die head. The size of the lumen determines the distribution of the solution across the width of the coating. The size and dimensions of the slot die opening are also important in forming a stable coating bead between the slot die and the substrate surface.

The slot die head is positioned above the moving substrate, and the height of the head relative to the substrate has a great influence on the coating quality. Most systems are controlled by micron or motorized stages. Some excellent systems allow the head to be tilted relative to the base plate so that there is variable clearance between the front and back of the head.

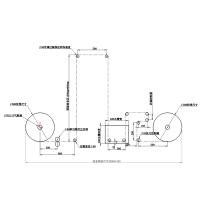

How does the substrate move relative to the printhead? In roll-to-roll systems, this is controlled by a roller that feeds the flexible sheet at a given speed. In a wafer-to-wafer system, a linear stage can be used to move the substrate; this approach is typically used for rigid substrates.

The way all these subsystems interact leads to the formation of a stable coating where the thickness of the deposited wet film depends on:

The speed at which the substrate passes through the slot die head

The rate at which the solution is dispensed from the slot die head

SolutIon Metering

Slot die systems require solutIon Metering because solution delivery has a significant impact on coating uniformity and the actual thickness of the film. The rate at which the solution is dispensed needs to remain constant because the rate at which the solution is dispensed from the metering system is directly proportional to the thickness of the deposited film. Any change in flow rate translates into a change in film thickness. Therefore, the metering system has very high tolerances.

Another important aspect is how the metering system provides a solution. Some delivery methods provide resolution in small discrete pulses rather than a constant rate, and the frequency of these pulses can lead to chatter defects in the film.

Additionally, the response of the delivery system can affect the rate at which the solution is delivered when used at different pressures. Therefore, pumps controlled hydraulically or pneumatically may have problems with solutions of different viscosities.

There are many ways to provide solutIon Metering. The type of pump used usually depends on several factors, including:

The maximum volume of the solution to be coated

Solution flow rate

Accuracy of flow rate

Properties of the pumped solution

system cost constraints

The types of pumps used for metering solutions in slot mold systems can generally be divided into two types of positive displacement pumps:

Peristaltic pumps, in which the volume of the solution container decreases, causing displacement of the solution

Rotary pumps in which a rotating element transfers solution from one side of the pump housing to the other

For the small volumes and low flow rates often encountered in laboratory testing, simple peristaltic pumps such as syringe pumps are suitable. In these metering systems, a piston or plunger is used to displace the solution. The rate at which the solution enters the slot die system depends on the rate at which the piston moves and the diameter of the piston.

With syringe pumps, the displacement is controlled by an electronic stepper motor, which helps maintain the displaced volume independent of pressure—provided that the force required to displace the solution is less than the motor can provide. For these dispensing systems, the step rate becomes important to avoid the formation of defects due to the pulse step of the motor.

For larger coating volumes and rates, these smaller systems are generally less suitable. Instead, use a rotary pump attached to a large solution container. In these systems, displacement is provided by a rotating element placed in such a way as to restrict the flow of the solution.

The volume pumped into the system is directly related to:

The speed at which the element rotates

Volume of solution passed per rotation

Compared to peristaltic pumps, the rotary pump approach reduces the impact of pulses on flow rates. However, since the displacement mechanism is consistent with a solution that protects the mechanism from damage and preserves the solution, contamination can be a problem.

Slot Die Design

One of the complex aspects of a slot die coating system is the design of the slot die head. The head controls the distribution of the solution over the entire coating width, the actual coating width of the film, and also helps determine the stability of the coating process.

Inlet and Manifold

For inlets, this location is usually in the middle of the system, near the top of the manifold. For wider slot die heads, multiple inlets can be used to reduce the size of the required manifold, as well as the length of the lands, pre-lands and slots. Once the solution is in the system, it starts filling the manifold.

Various designs can be used for this part of the slot die head, and this part has a great influence on the distribution.

To achieve the same flow rate across the width of the slot die, the manifold can be made in a coat hanger design. This is where the bottom edge of the manifold becomes closer to the outlet of the slot die (L 1 >L 2 ) as the distance from the inlet increases. Although the flow rate of the solution becomes more uniform across the width when using the hanger design, the shape of the hanger needs to be re-optimized for different flow rates and solution viscosities.

A modified form of hanger design called a "constant shear manifold" is available where the decrease in distance between the bottom edge of the manifold and the slot die exit is not linear. In contrast, the initial decrease in distance is small, and closer to the outer edge of the slot die, the distance decreases significantly (L 1 >L 2 >>L 3).

This design allows a constant flow rate (independent of solution viscosity and flow rate) across the width of the slot die. However, a constant shear manifold requires a longer landing length than other designs - at the same time, the manifold is much larger in volume. This increases the size of the required slot die head and the dead volume in the system, which results in increased initial setup and operating costs compared to simpler designs.

Lands, slots and spacers

Pre-lands, lands, and grooves within the die are all areas that restrict solution flow through narrow channels. The width of the channel and the length of the channel are of self-evident importance in controlling the pressure drop within the slot die, which helps to control the stability of the wet film coating.

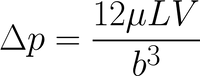

The flow of solution through these narrow channels is determined by the Pouiselle Flow equation (given by the equation below), where the pressure drop (delp) within the slot die head is determined by the flow rate of the solution (V), the viscosity of the solution (mu), the channel length (L) and channel width (b).

It can be seen that the parameter with the greatest amount of control over the pressure drop is the channel width. However, changing the channel length and width is very costly since a new head needs to be milled each time the channel is changed. This problem can be solved by using spacers of different thicknesses, which can enlarge the width of the channel.

The pressure drop can be maintained at a constant value by using different size gaskets for different flow rates or solution viscosities.

In addition to controlling the thickness of pre-pads, lands, and trenches, spacers can also be used to set the width of the coating. They can allow the deposition of fringe patterns and can be used as meniscus guides to improve edge definition. By having the slot thickness determined by shims, it is possible to prevent solution from flowing out of certain areas of the slot die.

To improve edge quality, meniscus rails can be added. These guides are spacers where a thin protrusion under the lip of the slot die head is used. The protrusions are placed where the striped pattern is desired and act to secure the meniscus to the spacer rather than the lip. This stops the menisci from spreading across the width of the head.

the lips

The lips of the slot die head design are the areas upstream and downstream of the exit slot of the head. In these areas, the menisci are fixed to the slot die head and the stability of these menisci can be strongly influenced by the design and positioning of these lips. An easy variation in lip designs is to change the length of the lips by adding length.

The two different geometries available for the lips are:

Standard configuration with equal clearance height for upstream or downstream lip

Underbite structure, the upstream lip gap is smaller than the downstream gap

The advantage of changing the configuration is that the stability of the upstream meniscus can be improved without changing the stability of the downstream meniscus.

Substrate positioning

The positioning of the slot die relative to the substrate is important to help stabilize the coated beads. In sheet-to-sheet and roll-to-roll systems, the machining and tolerances of the brackets (or rolls) that support the substrate can have a large impact on the gap height. Localized defects caused by surface roughness, bed flatness issues or roller concentricity can all cause variations in the gap height and stability of the coating bead over the length of the substrate.

The exact tolerances of the system will depend on the solution you are coating and the process parameters used.

When operating the system, the slot die head can be manually or automatically controlled to move to a position above the substrate. The advantage of automatic control is that online monitoring of film quality can be used as feedback for adjusting slot die height.

In addition, automatic movement allows rapid raising/lowering of the head, enabling highly defined leading and trailing edges in intermittent coatings. Typically, the height of the gap is determined by using a digital altimeter or micrometer. They attach to the head carriage and measure relative to the rollers or the top of the carriage.