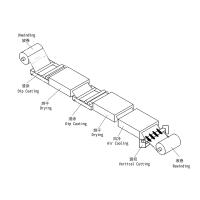

During dip coating, the substrate is immersed in a coating solution. As it is withdrawn, the liquid layer is entrained on the substrate. The thickness of this entrained solution is determined by the extraction speed.

advantage

Simple process and setup. It does not require a lot of training at first, and the specific thickness can be obtained by controlling a few parameters.

Suitable for coating on flat substrates. Also suitable for coating other surfaces such as pipes. Apply the coating to both sides of a flat substrate at a time.

Very uniform coatings can be produced with surface roughness in the nanometer range.

Gradient coatings can be achieved by varying the pull-out speed.

Adaptable between high-precision batch processes and large-scale processes.

By reducing the extraction rate, the process can be optimized for low concentration solutions.

A less expensive setup than other techniques such as slot die coating.

Small equipment size - the total bench area of the Ossila Dip Coater is 10cm x 30cm - you can use this technique in a small laboratory.

Significant drying time. Suitable for cases where time is required to form thin film structures.

shortcoming

During the drying phase, the wet film is susceptible to environmental factors such as turbulent air flow. These factors need to be actively controlled, so ideally the drying phase should be done in a clean room or using a laminar flow hood.

Difficult to coat curved or flexible substrates.

Depending on the solution, thin films may require post-deposition heat treatment. This can mean that less substrate can be deposited, increasing process costs. It also makes Graduation more difficult.

Material shrinkage (when changing from a liquid layer to a solid layer) can cause the film to crack. This effect is exacerbated for thicker films.

Dip coating requires a solution container for dipping the substrate. In order to obtain a uniform coating, it is important that the volume of the solution is much larger than that of the substrate. This results in a large amount of solution wastage.

ideal use

Dip coating was developed for large-scale manufacturing and is suitable for roll-to-roll processing. However, it can also be used for small batch experiments. Because dip coating is affordable, easy to master and easy to adapt to different needs, the process is often used to investigate simple thin film coatings. Dip coating is ideal for coating both sides of flat substrates simultaneously and can be used to create gradient coatings by varying the pull-off speed. This technique is commonly used in the study of protein coatings, protective coatings and tribological coatings.