Dip coating refers to immersing the substrate in a tank containing the paint, removing the workpiece from the tank, and allowing it to drain. The coated sheet can then be dried by force drying or baking. This is a popular method for creating thin film coating materials in conjunction with spin coating procedures.

dipping stage

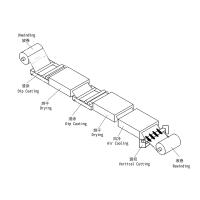

The dip coating process can generally be divided into 3 stages:

Immersion: The substrate is immersed in the solution of the coating material at a constant speed, preferably without shaking

Dwell Time: The substrate remains fully immersed and still to allow the coating material to spread itself on the substrate

Withdrawal: The substrate is again withdrawn at a constant speed to avoid any shaking. The faster the substrate is removed from the tank, the thicker the coating material will be applied to the board.

pros and cons

Due to its simplicity, this method is suitable for automation. Film thickness is controlled by paint viscosity and rate of withdrawal from the tank. Dip tanks come in a variety of shapes and sizes to accommodate large objects to be coated.

Dip coating also has its disadvantages, including: light parts tend to float off the conveyor; film thickness can vary from top to bottom (the "wedge effect"); a fat edge appears on the bottom of the part when excess coating is lost; and Solvent vapor reflux over the tank removed some of the coating.

brief theory

Dip coating technology can be described as a process in which the substrate to be coated is immersed in a liquid and then withdrawn at a well-defined withdrawal rate under controlled temperature and atmospheric conditions. Coating thickness is mainly determined by withdrawal speed, solids content and liquid viscosity. If the exit velocity is selected such that the shear rate keeps the system in Newtonian state, the coating thickness can be calculated by the Landau-Levich equation [1] (eq. 1).

Use: h = coating thickness, η = viscosity, γ LV = liquid-air surface tension, ρ = density and g = gravity.

The interesting thing about the dip coating process is that by choosing the right viscosity, the coating thickness can be varied with high precision between 20 nm and 50 µm while maintaining high optical quality.

Control of the atmosphere is required if a reactive system is chosen for the coating, as is the case in sol-gel coatings using alkoxides or prehydrolyzed systems (so-called sols). The atmosphere controlled evaporation of the solvent and subsequent destabilization of the sol by solvent evaporation, due to the small particle size (nm range) in the sol, resulted in a gel process and the formation of a transparent film.

In general, sol particles are stabilized by surface charges, and the stabilization conditions follow Stern's underlying considerations [4]. According to Stern's theory, the gelation process can be explained by the distance the charged particles approach below the repulsion potential. Repulsion then becomes attraction, resulting in very rapid gelation. This occurs at the gel point as shown in Figure 2. The resulting gel then needs to be densified by heat treatment, with the densification temperature depending on the composition. But due to the very small size of the gel particles, this system shows a large excess energy and in most cases a significantly lower densification temperature can be observed compared to the bulk system. However, one needs to take into account that the diffusion of alkalis in conventional glasses such as soda-lime glass starts at a few hundred degrees Celsius and, as shown by Bange, alkali ions diffuse into the coating during densification. In most cases this has no disadvantages as the bonding of the layers becomes perfect, but the effect on the refractive index needs to be taken into account in the calculations of the optical system.

Dip coating techniques are also applied to optical coatings such as light bulbs, optical filters or dielectric mirrors.