Wire pull testing is an established method for validating ultrasonic wire bond interconnects in microelectronics.

Pull testing involves a precision tool tip applying an upward (pull) load to the wire being tested while the workpiece or product component remains stationary.

As the tool moves upwards, the force (load) exerted on the work sample is accurately measured and recorded as the test result.

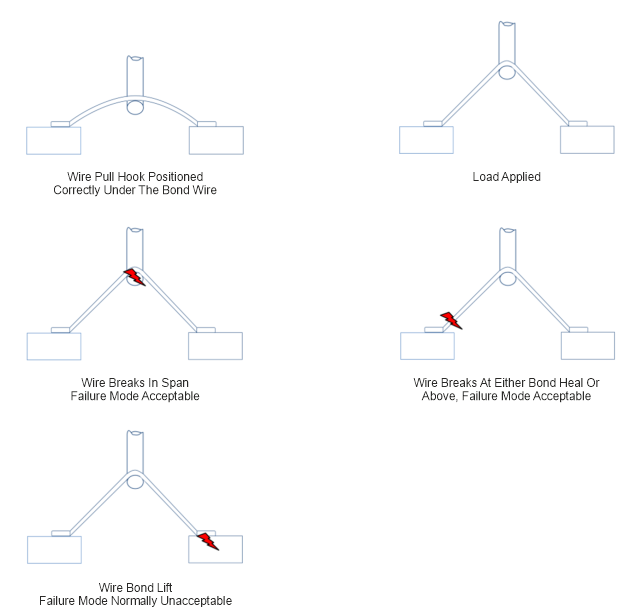

A standard wire pull test involves placing a suitable pull hook under the wire loop being tested.

The load is applied vertically (90°) to the workpiece under test.

Destructive testing tests the ultimate strength of a wire bond until it fails.

Non-destructive testing applies a predefined load to the wire under test for a predefined duration to test wire integrity on high-value components without damaging the interconnect itself.

Pull testing is available for ball bond, wedge bond and ribbon bond interconnects.