set gauge length

For fabrics with maximum force elongation ≤ 75%, the gauge length is (200±1) mm. For fabrics with an elongation > 75% at maximum force, the gauge length is (100 ± 1) mm.

elongation or elongation

Set the elongation or elongation of the Tensile Testing Machine according to the maximum elongation of the fabric under force in the table below.

Sample installation

Specimens can be mounted preloaded or "loosely mounted", ie hanging freely under their own mass. In the loose-fitting method, one end of the sample is clamped in the center of the upper jaw, and the other end is suspended in the lower jaw by its own mass, parallel to the direction of the pulling force, ensuring that the center line of the pulling force passes through the midpoint of the lower jaw, and the lower jaw is closed at the same time.

The initial length at maximum force extension is the sum of the gauge length and the elongation of the specimen to the specified pretension. The elongation of the specimen is measured from the point on the force-elongation curve corresponding to the preload. If using an electronic device to record elongation, be sure to use the correct initial length to calculate elongation.

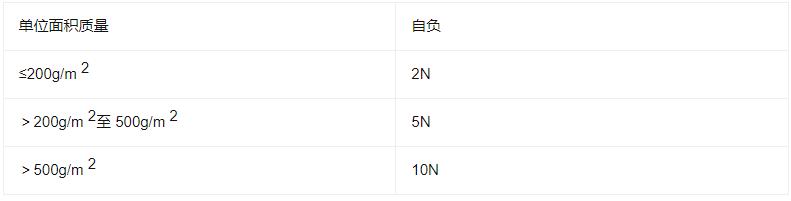

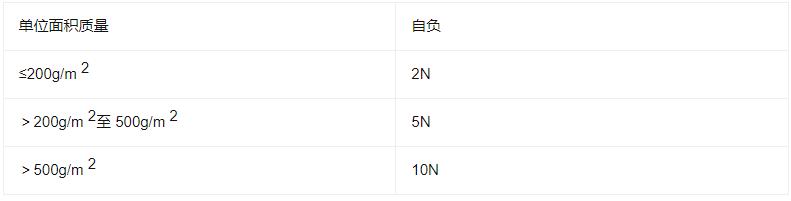

Install with preload, apply proper preload. Elastic fabric adopts 0.5N; for non-elastic fabric, use the required pre-tightening force according to the mass per unit area of the sample.

Tensile testing machine operation

Tensile testing machine operation

The tensile Tester is activated, causing the movable grips to move and stretch the specimen until it breaks. Record the force at maximum, elongation at maximum force or elongation at maximum force and, if desired, force at break, elongation at break, and elongation at break. Test at least 5 specimens in each direction and record the elongation or elongation at least to the nearest.

If the specimen slides asymmetrically along the jaw line or if the slide is greater than 2 mm, the test result is discarded.

wet sample test

Take the sample out of the aqueous solution, put it on absorbent paper to absorb excess water, and immediately carry out the test according to the above test procedure. For wet samples, apply half the preload specified for dry samples.

Calculation and presentation of results

Calculate the arithmetic mean of the maximum force for each test direction and, if necessary, the breaking force in Newtons. The calculation result is modified as follows.

Calculate the average value of the maximum force elongation in the warp and weft directions, and if necessary, calculate the average value of the elongation at break. The calculation results are modified as follows.

If necessary, calculate the coefficient of variation to the nearest 0.1% and the 95% confidence limits of the relevant properties tested, rounded to the same precision as the mean.