Importance of Auto Parts Salt Spray Test

The corrosion damage of automobile metal parts has become one of the important reasons for the reduction of the life of the current automobile.

Salt spray test is an important means to test the corrosion resistance of metal parts. test etc.

The neutral salt spray test is to place the sample in a salt spray box, use a spray device to convert a sodium chloride solution with a mass fraction of about 5% into salt spray for free settlement, so that the salt spray falls evenly on the surface of the sample, and keep Frequent renewal of saline solution membranes.

It can accelerate the corrosion of metal surfaces, and is suitable for metals and their alloys, metal or organic coatings, anodic oxidation films and conversion films, etc.

The acetic acid salt spray test and the copper accelerated acetic acid salt spray test are to add acetic acid or even copper chloride to the neutral salt spray to accelerate the corrosion process.

The cyclic salt spray test is a comprehensive salt spray test.

Through the neutral salt spray test plus constant humidity and constant heat conditions, through the penetration of humid environment, salt spray corrosion not only occurs on the surface of the product, but also inside the product.

The cyclic salt spray corrosion test can better test the real corrosion state of the sample, and it is also a very strict one in the salt spray test.

It is mainly used for components with complex structure and serious corrosion, such as exhaust pipe, frame, oil pipe, wiper arm, etc.

Principle of Cyclic Corrosion Salt Spray Test

Corrosion is generally divided into chemical corrosion and electrochemical corrosion.

Chemical corrosion refers to the corrosion of metals caused by chemical changes in dry gases and non-electrolyte solutions.

This corrosion does not involve water; electrochemical corrosion occurs under the action of electrolyte and water. Battery. In electrochemical corrosion, the metal with the lower electrode potential is the anode, and the metal with the higher electrode potential is the cathode.

The anode loses electrons and turns into metal ions into the electrolyte, forming anode corrosion, while the cathode accepts electrons and transfers them to the medium in the electrolyte. ions to keep the reaction going.

Due to the constant change of temperature and humidity, the cyclic salt spray test sometimes belongs to electrochemical corrosion under the intervention of water, and sometimes belongs to chemical corrosion without the intervention of water.

In the test, after the salt spray particles settled and attached to the surface of the material, they quickly absorbed water and dissolved into an aqueous chloride solution.

Or the pores of other materials penetrate into the material system, causing corrosion of the metal substrate.

The test generally carries out a multi-cycle process to simulate extreme climate conditions such as humid heat and dry heat in the actual environment, especially in the experimental stage of water evaporation and salt deposition, the high concentration of salt solution on the dry sample surface will lead to coating surface.

Corrosion rate increases. In addition, the corrosion reaction is directly accelerated due to the full contact of the sample surface with oxygen during the process of changing from wet to dry.

Commonly used cyclic salt spray test standards

National standard GB/T 24195 (equivalent to ISO 16151)

GB/T 24195 "Cyclic Accelerated Corrosion Test of Metals and Alloys" specifies two methods under acid salt spray, "dry" and "wet" conditions:

Method A is only applicable to metals and their alloys, metal coatings (cathode coatings), anodic oxidation coatings, organic coatings on metal materials, etc. Method B is mainly applicable to anodic coating of steel plate, conversion coating on steel, anodic coating leaflet, etc.

The corrosion process is divided into three stages: acid salt spray corrosion, dry maintenance and wet maintenance. The corrosion solution uses 5% acidic sodium chloride solution, and the pH is controlled at 3.5±0.1.

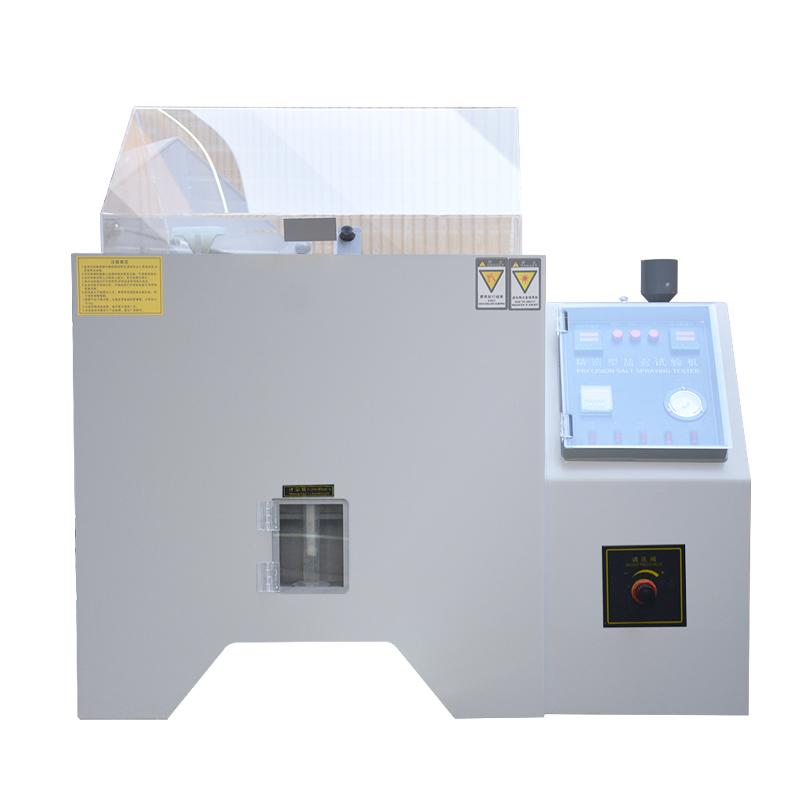

Ordinary salt spray Test Chambers only provide salt spray and temperature control, and do not have a drying function. Only a multi-functional salt spray Test Chamber (made of glass fiber) can provide you with a full-cycle corrosion salt spray test.

Method A requires the sample to be placed at an angle of 20°±5° to the vertical direction, the salt mist collection area is 80 cm2, and the salt mist deposition rate after continuous spraying for 24 hours should be within (1.5 ± 0.5) mL/h.

The test cycle is determined according to the corrosion degree of the parts, generally within 3 to 180 cycles.

The corrosion process is also divided into three stages: acid salt spray corrosion, dry maintenance, and wet maintenance.

The corrosion solution is a mixed acidified salt solution containing NaCl, MgCl 2 , Na 2 SO 4 , CaCl 2 , KCl, NaHCO3, KBr, H3BO3, SrCl2 and NaF. The pH was controlled at 2.5 ± 0.1.

The sample placement angle and salt spray deposition rate of method B are the same as those of method A, and the test cycle is also determined according to the corrosion degree of the parts, generally within 12 to 192 cycles.

According to GB/T 24195, after the test is completed, let it dry naturally for 1 hour, and then evaluate the sample after rinsing with clean water.

There should be no obvious change in the appearance after the test, and the number and distribution of corrosion defects meet the requirements of GB/T 6461

"Rating of specimens and specimens after corrosion tests of metallic and other inorganic coatings on metallic substrates" (equivalent to ISO 10289), mechanical and electrochemical properties cannot be altered.

VW Standard PV 1210

PV 1210 is the cyclic salt spray corrosion standard for Volkswagen body and accessories, and is a widely used cyclic corrosion test standard.

This standard is applicable to the corrosion test of samples such as painted body, body panels and structural parts.

The test is divided into three stages: spray salt spray, standard climate storage, and humid heat storage, as shown in Figure 3. Salt spray is carried out according to the NSS method in DIN 50021 standard, the mass concentration of NaCl is (50±5)g/L, and the spray time is 4 hours;

湿热储存符合DIN 50017标准中的恒定状态(KK)条件,(40±3)℃,100%湿度16h,5个循环后,在标准气候下储存2d在继续之前。

可进行15、30、60或90个循环的测试,然后判断样品的腐蚀情况,包括腐蚀类型(涂层或基体腐蚀)、腐蚀类型(平面腐蚀或边缘腐蚀)和腐蚀进程(附着力损失)情况,是否有气泡)。

通用汽车标准 GMW14872

GMW14872是通用汽车公司的循环腐蚀实验室测试标准,适用于汽车金属零件。

试验过程包括盐雾、常温储存、湿度储存、干燥储存等阶段,如图4所示。盐水喷雾阶段溶液组成为NaCl 0.9%、CaCl 2 0.1%、NaHCO 3 0.075%;

常温储存阶段,温度为(25±3)℃,湿度为45%±10%,存放8h;储存阶段,温度(49±2)℃,湿度100%,保存8h;在干燥储存阶段,温度(60±2)℃,湿度≤30%,8小时。

外饰件,每个周期喷盐雾4次,28个周期无表面腐蚀,52个周期无基材腐蚀;内饰件,5个循环喷一次盐雾,视部位而定,要求22个循环无表面腐蚀,40个循环无基材腐蚀;

对于发动机舱部件,最大要求是每个循环4次盐雾,9次无表面腐蚀,51次无基材腐蚀;用于车身底部部件,每个循环 4 次盐雾喷射,最多 6 次循环无表面腐蚀,68 次循环无基材腐蚀

克莱斯勒汽车标准 SAE J2334

SAE J2334是国际汽车工程师协会汽车腐蚀与防护委员会制定的装饰材料腐蚀实验室测试标准。

它适用于评估特定涂层系统、基材、工艺或设计的耐腐蚀性。

测试过程包括湿度储存、盐雾、高温储存三个阶段(见图5):湿度储存要求湿度100%,温度50℃,保持6小时;盐雾15分钟,溶液含0.5% NaCl、0.1% CaCl 2 和0.075% NaHCO 3 ;高温贮存要求温度60℃,湿度50%,贮存17小时45分钟。

For severely corroded exterior parts and opening and closing parts, such as wiper levers and B-pillars, C-pillar exterior panels, etc., there is no corrosion after 60 cycles, and no loss of function after 120 cycles; for the cockpit and interior, you can see Parts received, such as inward opening handles, seat headrest support brackets, etc., require 30 cycles without corrosion and 120 cycles without loss of function.

Nissan Engineering Standard M0158

Nissan's cyclic salt spray test provides 3 different cyclic methods for parts with different degrees of corrosion, as shown in Figure 6 to Figure 8.

The first method is suitable for general corrosion parts, such as body parts, fasteners, etc.

The whole cycle is divided into three stages: neutral salt spray corrosion, dry maintenance, and wet maintenance, with a total time of 8 h.

The second method is suitable for severely corroded parts such as outer panels, and the number of dry and wet maintenance cycles is increased on the basis of the first test cycle.

The third method is suitable for parts with severe internal corrosion, changing the neutral salt spray to salt water immersion, and the test conditions are stricter than the first two methods.

SAIC Roewe SMC 30054 ((equivalent to RES 30.CT.119))

SMC 30054 is the cyclic corrosion test standard of SAIC.

First spray with salt spray for 6 hours, and then store in high temperature, high humidity, and high temperature dry environments respectively.

The specific number of cycles depends on the degree of corrosion of the parts and the installation location, and is generally selected within the range of 20 to 720 cycles.

summarize

It can be seen from the above comparison that although the content of each standard is different, the basic test stages are roughly the same, including salt spray stage, dry stage, and wet stage.

The national standard GB/T 24195 divides circulating salt spray into two categories.

For different corrosion conditions, spray salt spray at different times.

It is highly pertinent and operable, and it is also the standard for using acidic salt spray conditions alone in the cyclic corrosion standard.

According to different test conditions and standards, European and American test standards mostly adopt the same cycle process, and use different cycle times to simulate different degrees of corrosion;

The Japanese standard subdivides the corrosion parts, and formulates different corrosion rates for different parts.

Standard, simulation is more realistic. Most domestic independent brand car companies do not formulate their own cyclic corrosion test standards but use foreign standards for reference. The corrosion requirements are relatively low, and cyclic corrosion tests need to be strengthened.

In short, the cyclic salt spray test can simulate the actual use of users through different temperature and humidity changes.

Compared with the neutral salt spray test, it can accelerate corrosion and better reflect the corrosion resistance of parts. Through the cyclic salt spray corrosion test, effective anti-corrosion control of metal parts in the early stage of development is of great significance to prolong the service life of metal parts.