Cartons are the most widely used packaging materials for commodities. With the increase in global trade, various types of commodity packaging materials such as paperboard and corrugated cardboard are used. In order to meet the requirements and expectations of your customers, it is necessary to test your cartons before any damage occurs while shipping or shipping your products.

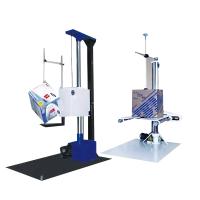

What is a Drop Tester and what will it be used for?

By performing a shock drop test, you can determine if a carton can withstand the rigors of being dropped during shipping and handling. If you are concerned about the impact resistance of your carton, then you should consider performing an impact drop test.

How does a Drop Tester work?

When you're looking for a way to improve your packaging design, Drop Testers can help. This machine is designed to help you test the strength of cartons. By performing a shock drop test, you can determine whether your packaging can withstand the rigors of shipping and handling.

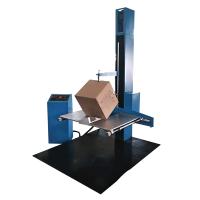

To perform this drop strength test , simply place the carton on the platform and select the desired drop height. The machine then drops the carton onto a hard surface, such as concrete. Data from the shock drop test can then be used to improve your packaging design.

Why Should Packaging Manufacturers Shock Drop Test Cartons?

If you're in the business of paper and packaging products or shipping or storing products, it's important to know how well your packaging can withstand shocks. This is where shock drop testing comes in . This type of testing simulates the types of impacts your packaging will experience during shipping, handling and storage.

1. Ensure product safety: Shock drop testing helps ensure your product is safe during shipping and handling. By simulating the types of impacts your packaging will experience, you can ensure your product will reach its destination safely.

2. Avoid damage to the product: In addition to ensuring the safety of the product, the impact drop test also helps to avoid damage. By understanding how your packaging responds to impact, you can design it in a way that minimizes the risk of damage.

3. Improve packaging efficiency: Shock drop testing can also help you improve packaging efficiency. By understanding how your packaging responds to impact, you can optimize its design for protection and waste reduction.

4. To reduce your shipping costs: By doing a carton drop test, you will be able to test the drop strength of your package.