We all know that adhesives are increasingly used in the packaging industry for effective packaging materials. They are strong and durable materials that help withstand the rigors of shipping. Therefore, it is very important for packaging material manufacturers to determine the strong and durable connection of these adhesives so that the material will not be damaged during transportation or transportation.

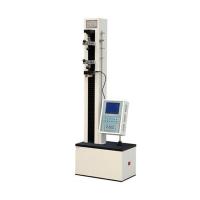

Accurately Test the Peel Ability of Adhesives Using a Peel Strength Tester

In the packaging industry, manufacturers make sure they use good materials so that the product remains intact and not damaged. But what ? It will definitely damage your product and cause huge loss of customers. Adhesive strength Testers will easily quantify the peel ability of adhesives and are manufactured to strict ASTM standards. You can easily determine the durability of an adhesive by determining its peel strength .

With the peel Tester, you can easily analyze the strength of the adhesive bond and test whether this strength testing instrument is suitable for use in the packaging industry. With the peel Tester, you can easily perform 90 degree peel strength test, 180 degree peel strength test and T-peel.

advantage

Easily measure the damage that will be done to a material when high forces are applied to it.

Test instruments come with built-in calibration facilities that allow you to set the device performance to your requirements.

A seal and bond adhesion Tester will allow you to test your material at different angles. This means that with this laboratory test equipment you can easily

Carry out 90 degree peel strength test and 180 degree peel strength test.

This test instrument is highly accurate and provides you with accurate test results.