overview

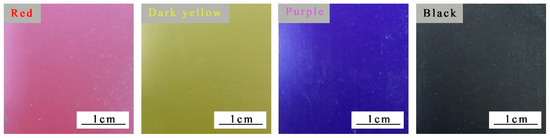

The effects of red, dark yellow, purple and black slurries on the properties of fluororesin/aluminum low-emissivity coatings were studied. The infrared emissivity coatings of red and black pastes are higher than those of deep yellow and purple pastes. Red, deep yellow and purple pastes have a hardness of 6H, and black pastes have a hardness of 6B. The dark yellow coating has better adhesion and impact resistance, followed by red and purple, and the black coating has the worst adhesion and impact resistance. The electrochemical polarization curves show that the purple slurry fluororesin coating has better corrosion resistance. Tested for salt water resistance, there was no appreciable loss of light in the coating of the four colorants. The purple paste coating has no obvious light loss and less air bubbles, indicating that the fluororesin/aluminum low-E coating of purple paste has better performance. The results of this study provide new perspectives for the application of infrared low-emissivity coatings in infrared stealth and compatibility with visible light.

1 Introduction

At present, research fields related to infrared light are more and more applied in the military field. Therefore, infrared low-emissivity coatings (IRLECs) have attracted increasing attention, since infrared emissivity is an important indicator [1]. IRLEC is part of infrared stealth technology [2]. Some universities and research institutions have carried out in-depth research on IRLEC. Dong et al. [3] studied the reflective properties of terahertz mid-infrared low-emission camouflage coatings. Li et al. [4] prepared a multilayer AlCrN/Cr/AlCrN coating on a nickel substrate by cathodic arc ion plating for low infrared emissivity applications below 750 °C. Wang et al. [5] used polyethylene glycol (PEG) 400 and inorganic silicate binder to modify CeO with 2 different contents of fillers to prepare coatings with excellent thermal shock resistance and low-temperature infrared emissivity. Corrosion is a problem because it limits the application of the coating. Corrosion protection is usually carried out by coating. The researchers mentioned above mainly focused on reflective properties, thermal shock resistance, and infrared emissivity, while paying less attention to corrosion resistance, color [6], and compatibility with visible light. The infrared coating is required to have the following properties at the same time: low emissivity, environmental protection, good corrosion resistance, low gloss, so that it has a good effect on visible light compatibility. Fluorine resin is environmentally acceptable, not only has high surface hardness, good adhesion and corrosion resistance [7, 8], but also can increase the water contact angle of the coating to achieve super-hydrophobic properties [9, 10, 11 ].

Paint color is one of the important indicators of paint decoration performance, but different colors can resist different visible light detection [12]. For stealth coatings, in addition to low infrared emissivity, compatibility with visible light stealth also needs to be considered [13]. Therefore, it is necessary to reduce the brightness of the coating and tint it [14]. Different colored slurries can change the coating color of IRLEC; however, there are few reports on IRLEC [15]. This paper is mainly aimed at the problem of color matching, and aims to study the effects of quantitatively changing the amount of different color pastes of red, deep yellow, purple, and black pastes on the infrared emissivity, gloss, brightness, adhesion, impact resistance, corrosion resistance and The impact of roughness, and then to obtain low gloss and better color of IRLEC, lay the foundation for the application of IRLEC and the compatibility with visible light in engineering.

2. Experimental part

2.1. Experimental materials

Fluororesin (JF100) and curing agent: Juhua Group Co., Ltd., Quzhou, CHINA 4017 aluminum powder (Mw: 26.9815 g/mol, CAS number: 7429-90-5, diameter: 10 μm, thickness: 220 nm, 65.0% Al powder mixed with 35.0% oleic acid): Zhangqiu Metal Pigment Co., Ltd., Zhangqiu, CHINA. Red 8011 (solid concentration: 25.0%), deep yellow 8032 (solid concentration: 25.0%), purple 8005 (solid concentration: 15.0%), black 9927 (solid concentration: 20.0%): Suzhou Shiming Technology Co., Ltd., Suzhou, CHINA . Technical aluminum plate [16]: 100 mm × 50 mm × 1 mm, Nanjing Chengxiang Aluminum Co., Ltd., Nanjing, CHINA.

2.2. Preparation of the coating

Sandpaper is used to polish the pre-treated substrate and degrease it, then dry in the oven. According to previous research experience, when the color paste content is 40%, the coating has good performance [17]. The solid content of aluminum powder and color paste means that the quality of aluminum powder and color paste is directly proportional to the mass of primary aluminum powder and color paste under vacuum (105±2) °C, where the aluminum powder and color paste are heated for 30 min . Determine the solid content of the fluororesin and the solid content of the curing agent by the same method.

Coatings were prepared according to the molecular formula in Table 1. After mixing, the coating is applied to the surface of a flat technical aluminum sheet. They were cured at 40°C for 2 hours in a forced air dryer. The thickness of the dry coating is about 60 μm.

Table 1. Composition of pastes of different colors.

2.3. Testing and Characterization

The specific information of the experimental test equipment is shown in Table 2. The infrared emissivity of the coating was tested in the range of 8-14 μm. In the corrosion resistance test, electrochemical tests were performed using a three-electrode cell structure. A saturated calomel electrode was used as a reference electrode and a platinum electrode was used as a counter electrode. The samples were immersed in 3.5% NaCl solution for 30 min, and the open circuit potential (OCP) was monitored until constant. After the open circuit potential is stabilized, the polarization test is performed. The test range is ±0.25 V of the open circuit potential. The coating was immersed in 3.5% NaCl solution for 7 days, and the salt water resistance test was carried out. All experiments were repeated four times with an error of less than 5.0%.

Table 2. Experimental test equipment.

| suject | standard | equipment |

| thickness | - | JKTH-1250B Digital Coating Thickness Gauge |

| Surface Structure and Morphology | - | JSM-5610LV scanning electron microscope |

| Infrared emissivity | - | Bruker Vertex 70 Infrared Emissivity Tester |

| luster | GB/T9754-2007 | BGD512-60 Vanke instrument |

| Impact resistance | GB/T 20624.2-2006 | QCG paint film impact testing machine |

| Adhesion | GB/T 4893.4-2013 | QFH Coating Adhesion Tester |

| hardness | GB/T6739-2006 | QHQ-A coating Hardness Tester |

| chromatic aberration | GB/T 3181-1995 | SEGT-J Colorimeter |

| roughness | GB/T 13288.5-2009 | JB-4C precision roughness Tester |

| Corrosion resistance | GB/T15748-2013 | CHI660E electrochemical workstation |

| Salt water resistance | GB/T15748-2013 | Beaker for 3.5% NaCl solution |

3. Results and Discussion

3.1. Infrared spectrum of color paste corresponding to coating

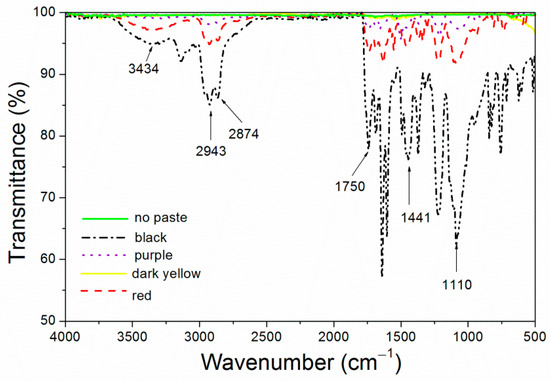

The infrared spectra of the four color pastes corresponding to the coating are shown in Figure 1. The peak assignments are shown in Table 3. There is an obvious -OH absorption peak at 3434 cm−1. 2943 cm−1 is the peak absorption of -CH3. 2874 cm−1 is the peak absorption of -CH2. 1750 cm−1 is the -C=O-absorption [18, 19]. 1441 cm−1 is the -COO absorption peak[20]. The obvious CF3 absorption peak appears at −1 at 1110 cm [21].

Figure 1. Infrared spectra of coatings with different colored slurries.

Table 3. Assignment of peaks.

The infrared absorption peaks indicate that the fluororesin forms a covalent bond. According to Kirchhoff's law, in thermal equilibrium, the infrared energy absorbed and emitted by an object is equal [22]. As shown in Figure 1, the infrared peaks of the purple coating, the dark yellow coating, and the paste-free coating are relatively flat, with less infrared absorption, and the emissivity of the corresponding coatings is lower (Figure 1), which is beneficial to reduce the surface emissivity [23 ]. The black coating has more infrared absorption, so the surface emissivity is the highest, which is not conducive to the preparation of low infrared emissivity coatings.

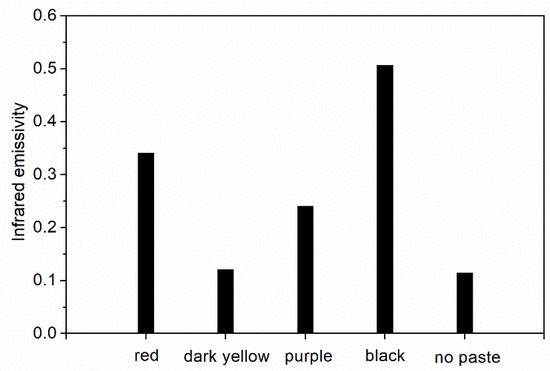

3.2. Effect of color paste on coating infrared emissivity

The influence of different color pastes on the infrared emissivity of fluororesin coatings is shown in Figure 2. The fluororesin coating made by adding red and black pulp has a high infrared emissivity (>0.3). The deep yellow and purple pastes make the fluororesin coating have a low infrared emissivity (0.10~0.25). The IR emissivity of the dark yellow paste is lower than that of the purple paste. This is due to the dark yellow paste having the lowest IR absorption (Figure 1) and stronger reflectance compared to the other colorants used in the experiments. The dark yellow paste has the lowest IR emissivity [24].

Figure 2. The effect of different color pastes on the infrared emissivity of the coating.

The SEM images of the coatings with different colors are shown in Fig. 3. There are more particles in the red and black coatings, but almost no microscopically obvious particles can be seen in the dark yellow and purple slurries, and the coatings are more uniform, which reduces the absorption of infrared light and reduces the infrared emissivity [25 ]. More particles and voids increase the IR absorption of the coating (Figure 1), and thus the IR emissivity of the red and black coatings increases.

Figure 3. SEM images of different color coatings: (A) red, (B) dark yellow, (C) purple and (D) black.

3.3. Effect of color paste on coating properties

The effects of different color pastes on the coating properties are shown in Table 4. As shown in Table 4, red and black pastes can give fluorine coatings a lower gloss compared to deep yellow and purple pastes. Black coatings have the lowest gloss. This is because coatings with red and black pastes have a stronger ability to absorb and emit light, but are less able to reflect light, thus exhibiting lower gloss [26].

Table 4. Effect of colorants on coating properties.

不同颜色的浆料对涂层的硬度有不同的影响。红色、深黄色、紫色涂层和无糊涂层硬度为6H,黑色涂层硬度最低(6B)。这是因为黑色糊状物主要由炭黑颗粒组成。与其他三种浆料相比,炭黑颗粒更疏松,影响涂层的致密性[27]。对于低红外发射率涂层,一个重要的作用是保护覆盖层,因此硬度不能太低[28]。可以看出,添加黑色膏体的涂层硬度不符合基本硬度指数(2H)[29]。对于黑色涂层,为了确保涂层能够满足基本硬度指数,可以通过添加改性剂来增强硬度[30]。

表4表明,无糊剂涂层的附着力推荐。深黄色涂层的附着力更好,黑色涂层的附着力最差。这是因为从微观角度看,深黄色涂层更均匀致密,组分易于混合均匀,而黑色糊状的炭黑颗粒与涂层其他成分之间的相互作用较少,因此很难与它们均匀混合[31]。不同色浆对涂层抗冲击性的影响不同。黑色涂层的抗冲击性最低,而深黄色涂层和无糊涂层的抗冲击性最高。这是因为深黄色涂层和无糊涂层具有高附着力。良好的附着力可进而保证良好的抗冲击性。带有黑色浆料的涂层附着力相对较小,冲击时容易脱落[32]。

如表4所示,深黄色和紫色涂层的粗糙度较低,表面更光滑。黑色涂层的粗糙度最高。这可能是因为深黄色和紫色浆料的粒径较小,可以填补涂层中铝粉之间的间隙并增加涂层的致密性。黑色糊状物的炭黑颗粒聚集在一起形成大颗粒,从而增加了粗糙度[33]。

表5是四种色浆对涂料色差的影响。色差是指涂层的整体亮度和色调的差异[34]。L、a和b分别代表不同颜色涂层的亮度、红绿色和黄蓝色值。L',a'和b'代表基板本身的这些值。相差Δ L、Δ a和Δb相差相减得到,分别表示为亮度差、红绿指数差和黄蓝指数差。 因此,色差ΔE可以According to公式[35]获得。

表 5.色浆对涂层ΔE的影响。

According to表5,不同色浆对涂料色差的影响是不同的。紫色浆料的色差与红、深黄、黑膏相比最小。同时,紫色涂层的L值最低,使涂层颜色较深。其他三种涂层的L值较大,亮度更高。

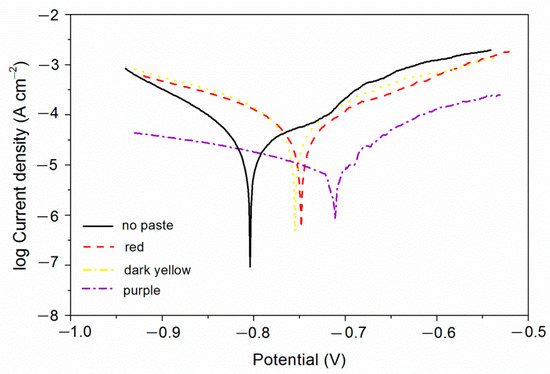

From the above studies, it can be found that the coatings with purple, red and deep yellow pastes have better comprehensive performance. Therefore, the electrochemical corrosion performance of these three coatings was tested. The test results are shown in Figure 4 and Table 6. βa and βc are the anodic and cathodic Tafel slopes, respectively [36]. The unit is mv/dec, mv means voltage, and dec means logarithmic current. The higher the potential E Cole, the larger the resistance Rp, the smaller the current I Cole and the better the corrosion resistance.

Figure 4. Electrochemical profiles of different colored slurries.

Table 6. Effect of different color paste content on corrosion resistance.

Test the salt water resistance of the four-color paste coating soaked in 3.5% NaCl solution for 7 days, and observe the change of the surface condition after a certain corrosion time. Light loss, discoloration and foaming density during actual corrosion of the paint film were evaluated. When the light loss is <3%, 4–15%, 16–30%, 31–50%, 51–80% and >80%, respectively, the degree of light loss of the coating is 0, 1, 2, 3, 4 and 5 levels. When the color difference changes before and after salt water resistance are <1.5, 1.6–3.0, 3.1–6.0, 6.1–9.0, 9.1–12.0 and >12.0, the degree of light loss of the coating is non-discoloration, very slight discoloration, slight discoloration, and obvious discoloration , severe discoloration and complete discoloration, the grades are 0, 1, 2, 3, 4 and 5 respectively. The test results are shown in Table 7 and Table 8 and Figure 5.

Figure 5. Foaming curves of fluororesin coatings for red, deep yellow, purple and black pastes.