The release film is a film that can be distinguished on the surface of the film. The common one is a release silicone film formed by scraping silicone on the PET film. The application of the release film is very extensive, commonly used terms such as decorative film, protective film and so on. Therefore, the release film is also commonly used in experimental research, and different sample slurries are scraped on the release film to study the performance of the film.

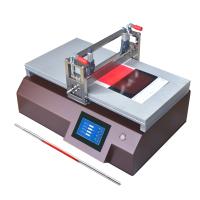

This article shares the experimental case of scraping the slurry on the release film on the experimental coating machine. The release film is a thin film, and a film coating machine with vacuum adsorption function is needed to better absorb and smooth the film, which is helpful for the uniformity of the coating film.

Since the slurry coating film in this case is relatively thin and requires high precision, an RDS wire Bar Coater is used for coating to ensure the accuracy and uniformity of the coating film. Due to the relatively high viscosity of the slurry used in the case, the speed of the scraping process should be relatively slow. Before looking at the specific experimental process, first look at the effect of the coating film.

Let's take a look at the specific experimental process of coating the slurry on the release film. Remember to pay attention to the details of the technician's operation in order to ensure a better effect of the coating film.

Do you have any problems in the process of scraping the film, welcome to communicate with Beichao Technology.