lighting calibration

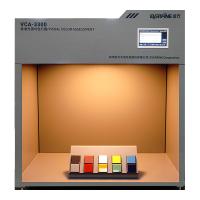

The light box or visual colorimetric camera is used for product visual evaluation, sample comparison, standard and sample comparison, color difference evaluation between products or materials, etc. These devices standardize the influencing parameters in the visual evaluation of color, specifically, the type of lighting and the background.

There are many industrial sectors that use visual comparisons of colors. Therefore, it is very common in the textile industry, the cosmetics industry, paint and varnish manufacturers, the toy industry or the automotive industry, among others.

A light box is an analog instrument with controlled, known and reproducible illumination. It usually has a neutral background so that comparisons can be made between two objects even if they are made of different materials.

There are different forms of light boxes, from those that look like 'boxes', to lighting systems that are located in large areas such as production lines, where the aim is to generate an ambiance of lighting control, so the impact of general lighting is minimized.

Comparison of colors in a controlled manner and under specific lighting conditions allows the observer to perform verification of metamerism.

Metamerism is a psychophysical phenomenon in which two colors appear the same under certain lighting conditions. So when the lighting conditions change, the two colors appear different. Metamerism is a common problem in products such as paints and inks. In these cases, it is recommended to visually observe two color samples, or one color sample and its pattern, under two different lighting conditions, such as illuminated daylight (simulated daylight) and Type A lighting (ie incandescent).

Guidelines to be followed when making visual comparisons of colors are contained in various international standards such as: ISO 3664:2000, ASTM D1729-96, ASTM D2646-96, ASTM D4086-92ª. Among other issues, these standards describe the characteristics that lighting booths need to meet in order for these devices to ensure proper evaluation. These characteristics are: light type, light level, and background and uniformity characteristics.

Type of lighting (light source)

Lightboxes have different types of lights for color evaluation. Light box manufacturers try to make the spectral output of a light source as similar as possible to a standard light source.

We can evaluate light sources by the following parameters: their correlated color temperature (CCT), tristimulus values (XYZ) and color coordinates (xy). Another parameter to consider when evaluating a light source is the color rendering index (CRI) of said light source relative to its corresponding light source. In this way, we can say that the higher the color rendering index, the more similar the light source is to the light source for the color perception of two samples or products.

To ensure that the lighting conditions inside light boxes remain constant, it is necessary to regularly check and calibrate the light sources of these light boxes. The importance of proper maintenance of lighting conditions cannot be overemphasized for industries and sectors where light boxes are used, as these conditions affect the evaluation of color and thus the acceptance or rejection of products.

Type A source

These light sources correspond to light source A, a type of incandescent tungsten lamp. Light source A is described in the CIE 15 standard by its spectral distribution. The color temperature of this lamp is about 2700 Kelvin.

daylight font

The light source Daylight represents the different phases of sunlight. The correlated color temperature of the light source D75 is about 7500K; as far as it is concerned, the color temperature of the light source D65 is about 6500K; the color temperature of the D50 is about 5000K.

Fluorescent source

The TL-84 fluorescent source attempts to primarily reproduce the F11 light source, a narrow-band trichromatic fluorescent lamp with a color temperature of approximately 4100K.

lighting level

The intensity or illuminance of the light source should vary according to the object (standard and sample) and the details to be evaluated. So for example, while about 500lx might be sufficient in an evaluation where appearance is not important or in a general evaluation, in an evaluation where the perception of detail is sought, this value will not be sufficient, so in this case it would suggest Use lighting around 2000lx.

On the other hand, it should not be forgotten that light sources in the same cabin may experience changes in lighting levels due to different reasons, such as power supply changes, aging of luminaires, environmental conditions, cleaning of lighting room components, etc.

Evenness

Uniformity across the lightbox area is a factor to consider. It is necessary to ensure that the lighting is constant and that there is no significant difference between the center of the cabin and any of its corners or sides.