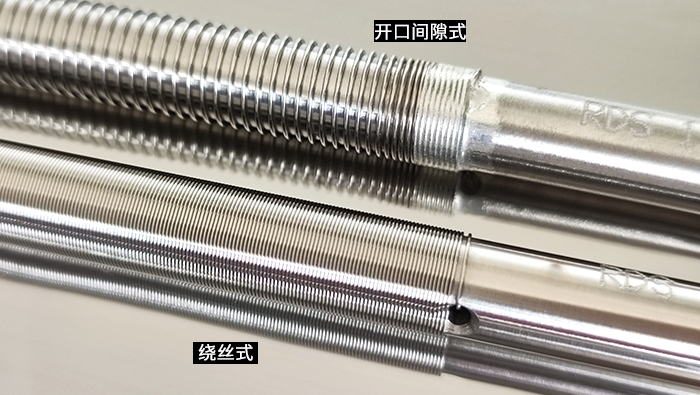

Traditional Wire Winding Spreader is usually used to prepare sample films with viscosity below 1000 cp, because its winding is relatively tight, it is easy to scratch and affect the coating effect when preparing high viscosity samples.

Gap type wire rod, winding gap is relatively large, can reduce blockage, eliminate scratches, suitable for Moulding of high viscosity samples above 1000cp.

So what are the advantages of RDS Open Spreader over Wet Film Applicators?

1. Higher precision

Inheriting the high precision of RDS wire 1 micron. Applicators can only reach ± 2 μm.

Larger coating widths. RDS wires have a coating width of 300mm, while Film Applicators have a maximum film width of 200mm.

2. Multi-layer coating

For the production of multilayer films, I-type preparation is not suitable, and the wire Spreader can realize the production of multilayer films.

3. Cost-effective

303 high-grade stainless steel wire, 304 stainless steel rod, wear-resistant and anti-corrosion.