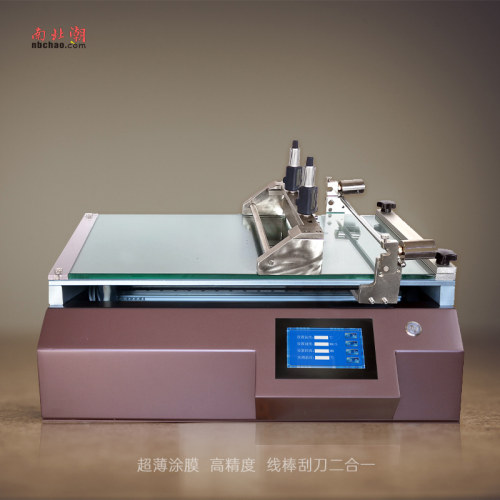

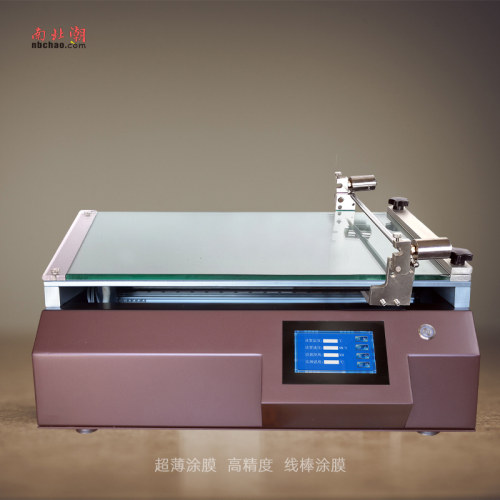

Automatic Film Applicator, as the name suggests, is "a machine for film". Modern laboratories have higher and higher requirements for Moulding, and some fields have become thinner and thinner. Although the preparation accuracy of hand-scraped film with Mayer wire rods is already very high, for ultra-thin films (such as preparing 1.5μm), Spreader table, film substrate and manual uneven pressure and speed are all prone to deviation. Some materials (such as hot-melt adhesives) need to flow under heating conditions, so the satisfaction of these needs is indispensable. The help of Automatic Film Applicator.

Through hundreds of experimental cases, NBCHAO sorts out Automatic Film Applicators that provide different functions for users, and deepens the understanding of Automatic Film Applicators among laboratory technicians.

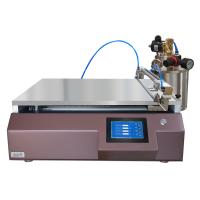

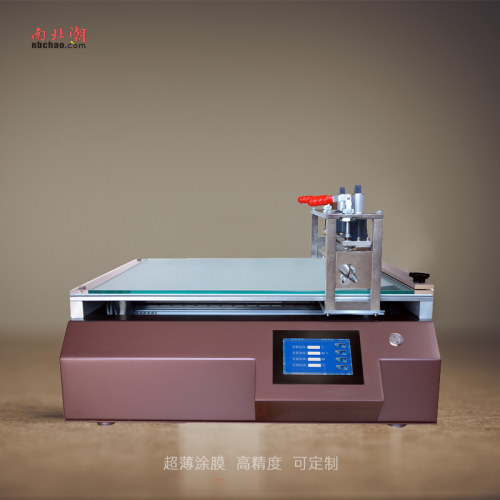

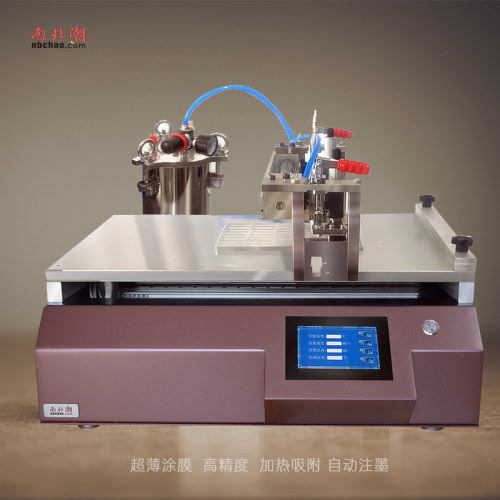

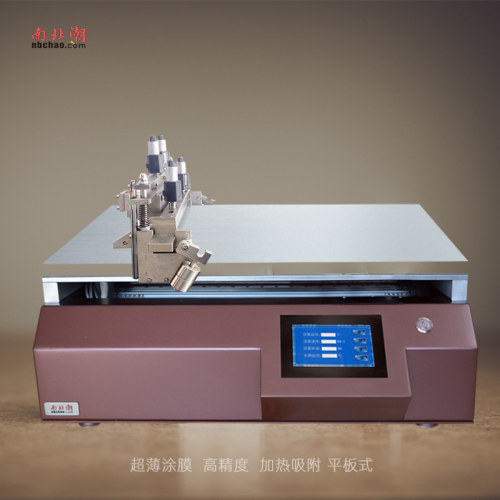

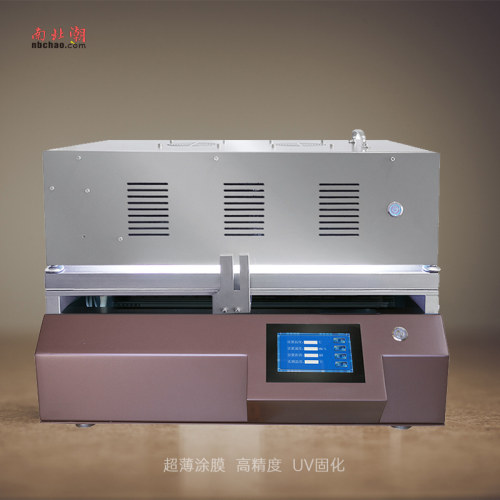

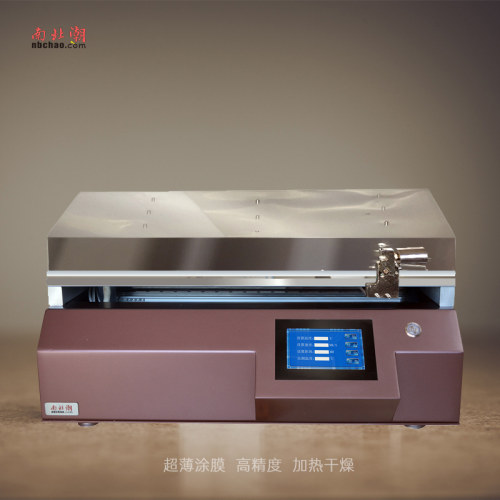

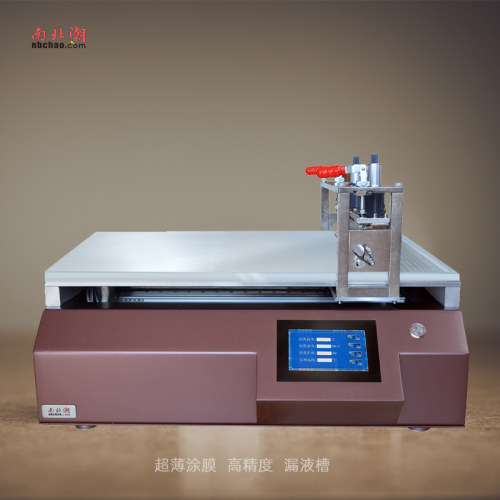

Types of Automatic Film Applicators

Application of Automatic Film Applicator

Different Automatic Film Applicators have different functions, and the application is of course different. Many people may have thought that some materials are drying slowly. If the film thickness is large, it is also very troublesome to send it to the Drying Oven for drying in the wet paint state. Why can't it be dried "on the spot"? So there is a top heating and drying function. Thermally modified materials such as hot melt adhesives need to be heated above 100 ℃ to become fluids, so the film can be scraped in a controlled amount, so the heating function needs to be used. And so on, can you think of where the Miscellaneous type Automatic Film Applicator can be used? Might as well think about it?

In addition, Automatic Film Applicator can also provide customization of different Coating sizes and customized solutions for special materials. For details, please consult NBCHAO.