In the past, NBCHAO’s film coating machines were used to automatically coat films, fabrics, paper, metal sheets, foils, and silicon wafers. This case is another new substrate application—glue on sponge sheets. So what kind of automatic scraping machine is more suitable for applying glue on the sponge, and what are the needs of users? Let's explore together.

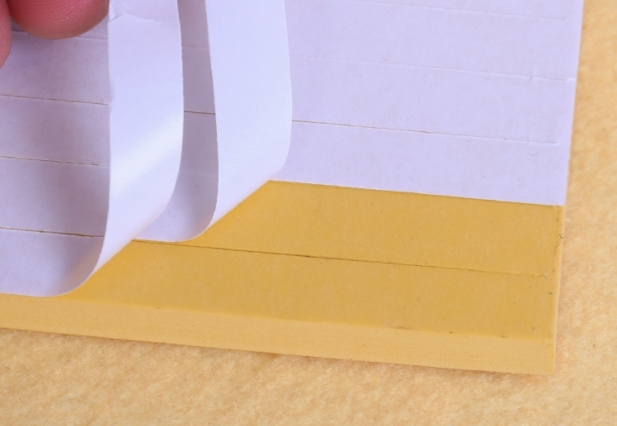

Glue on the sponge, a typical application is sponge glue, also called adhesive sponge, with EVA foam as the base material, one or both sides coated with solvent (or hot-melt) pressure-sensitive adhesive, and then easy to peel off Made of isolation paper. Sponge glue is different from glass tape, because sponge is light, soft, elastic, not easy to transfer heat, and has the functions of shock absorption, sound insulation, impact buffer, and heat insulation. Therefore, it is more and more widely used in various industries such as automobile decoration, heat insulation, and electrical refrigeration engineering.

In this user case, the customer scrapes and applies thick glue on the sponge sheet, the thickness of the applied glue is 2mm, and the wet film needs to be dried quickly after the application. According to the user's situation, the sponge sheet has a certain thickness and shape, so it is not necessary to choose vacuum adsorption, but can be fixed with a clamp, and the thickness of the glue 2mm is 2000 microns, which is relatively thick, and the wire rod cannot reach such a thickness, so it can be selected. The scraper is used as a film coating device. In addition, the customer hopes to automatically dispense glue, and finally selects the heating scraper automatic film coating machine and then customizes it with automatic feeding function.

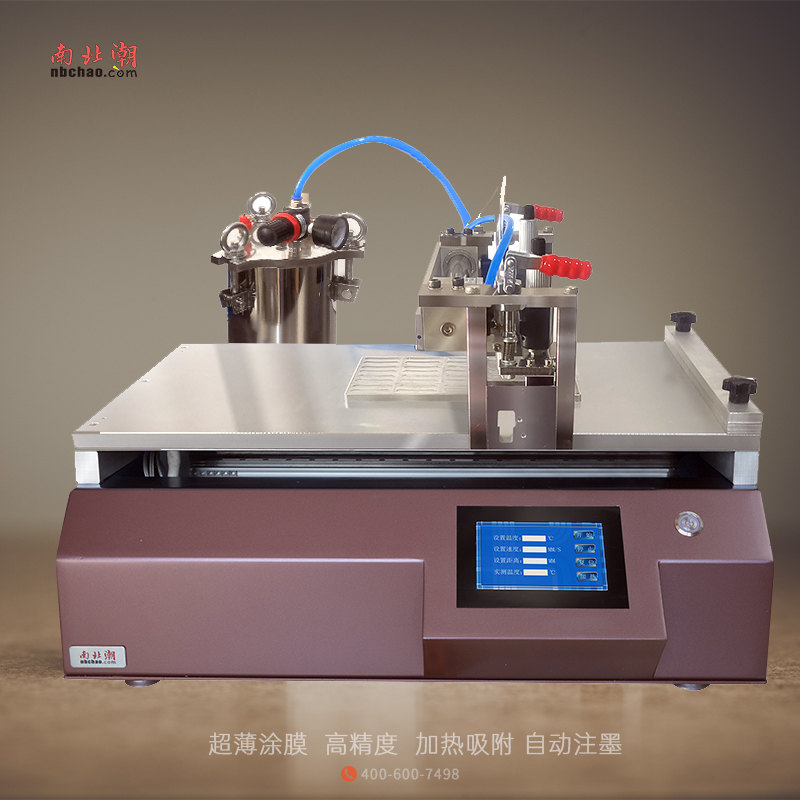

The following are the detailed technical parameters of the scraper heating automatic feeding film coating machine for reference. If you have any questions, please consult the technical engineer of NBCHAO.

| Membrane Proofing- Membrane | |

| Domestic TBJ-B3 Heated Blade Coating Tester |

| Specification parameters: coating precision ±0.003mm, coating thickness range 0.2~10mm, coating speed 2~200mm/s, coating width 300*400mm, digital display of coating time, different speed, time precision control, heating Temperature range RT+~200°C, temperature uniformity ±3°C, scraper length 400MM material/stainless steel, host power supply 220V 50HZ 1700W, overall size 690*410*520mm, net weight 65KG, speed control infinitely variable speed control, base plate material aluminum alloy, optional Optional accessories: liquid leakage tank, substrate fixing fixture, fine-tuning level height support leg device, glass plate, silicone pad and weight (for the application of uneven coating substrate thickness), coating film width control baffle, and customized function air jet System device, UV solid containing device, automatic ink filling system | |

| Domestic TBJ-X4-DJ3 vacuum adsorption wire rod heating integrated coating testing machine |

| Specification parameters: coating speed 2~200mm/s, coating width 300*400mm, coating speed digital display, different speeds, vacuum adsorption size 300*400mm (customizable), vacuum hole diameter Φ1.2mm, vacuum hole distance 20 *20mm, speed control stepless speed change, base plate material aluminum alloy, coating accuracy ±1μm, heating temperature range RT+~200°C, temperature uniformity ±3°C, automatic ink filling system with customizable functions, feeding principle air source pressure flows outward, The feeding movement mode is reciprocating linear motion, the feeding speed is 2-150mm/s, the discharge volume is adjustable (by adjusting the air pressure and the running speed of the outlet), the shaft transmission is synchronous belt, the gas source of the feeding system is 0.6Mpa, It can be connected to φ8 air pipe (self-configured). The power and voltage of the feeding system is 220V, 50Hz. The maximum pressure of the feeding barrel can withstand 8Mpa. The material of the feeding barrel is 304 stainless steel with a wall thickness of 4mm. Air Valve, Optional Accessories Leak Tank, Substrate Fixture, Fine Adjustment Leveling Foot Set, Glass Plate, Silicone Pad and Weights (for applications with uneven substrate thickness), Film Width Control Baffle, Dimensions 630*410*520mm, feeding tank volume 1L | |