composition

Polyurethane resin is polymerized from polyisocyanate and polyol, and its molecular structure contains a polymer compound with a heavy chain of carbamate, so it is called polyurethane for short. It was originally invented by Otto Bayer and others in Germany in the early 1930s. In the 1950s, polyurethane resins began to be used in the coatings industry.

NCO has high reactivity in polyurethane molecules. Therefore, polyurethane coatings can be cured at high temperatures and applied at low temperatures. For example, polyurethane coatings can be cured normally below 0°C, while epoxy resins are difficult to cure below 10°C.

Classification

Polyurethane coatings can be divided into two categories: one-component and two-component.

One-component polyurethane coatings include polyurethane oil, polyurethane alkyd resin, moisture curing polyurethane, blocked polyurethane; polyurethane dispersion system, etc.

Polyurethane oil and polyurethane alkyd resin have better alkali resistance, water resistance and abrasion resistance than ordinary alkyd resin coatings.

The moisture-curing polyurethane coating contains NCO end groups, which react with moisture in the air to form a urea bond cured film under ambient humidity. It not only has the excellent performance of polyurethane coatings, especially good abrasion resistance, but also has the characteristics of convenient application of single-pot coatings. The drying speed of moisture-curing polyurethane coatings is greatly affected by temperature, and if the temperature is too low, it will dry slowly. Since urea bonds will be produced during the film forming process, a large amount of CO: will be produced, so the paint film should not be applied too thickly.

The film-forming material of the closed polyurethane coating is composed of two parts: polyisocyanate and polyhydroxy resin. The isocyanate is blocked by phenol or other monofunctional substances containing active hydrogen atoms, so the two parts can be packaged together without reaction and have good storage stability. High temperature baking is required during construction, and the sealant volatilizes after baking.

Dispersion-type polyurethane coatings mainly introduce polar groups or hydrophilic groups into the molecular chain to form a stable high-molecular-weight resin water dispersion system.

Two-component polyurethane coatings with -NCO-based components and -OH-based components react in proportion to form polyurethane coatings. In order to promote the rapid drying of the film, a small amount of catalyst is often added to the hydroxyl component.

Polyurethane coatings made of aromatic isocyanate TDI are low in price and have good overall performance, but the paint film will turn yellow seriously after exposure to sunlight, easily lose light, and have poor weather resistance. Therefore, it is often used as a primer, intermediate paint or dark paint for interior use. use. The yellowing is mainly due to the decomposition of polyurethane bonds and amines after ultraviolet radiation, and the amines are oxidized again, so the film will turn yellow.

Aliphatic isocyanates, such as polyurethane coatings based on hexamethylene diisocyanate (HDI), have excellent weather resistance, color and gloss retention, and good decorative properties. Used to prepare topcoats with good outdoor weather resistance and decorative properties. The main reason for non-yellowing is that the aliphatic amines formed by urethane bonds are not easily oxidized, and there is no co-reaction of benzene rings.

In - NCO/- OH two-component polyurethane coatings, commonly used polyhydroxyl resins include polyester resins, acrylic resins, polyether resins, epoxy resins, castor oil and their processed products.

Polyester polyurethane paint film has high cross-linking density, hard and bright paint film, good chemical resistance, good solvent resistance, good weather resistance and good heat resistance.

Acrylic polyurethane coating is formed by the reaction of hydroxyl-containing acrylate and HDI trimer and other aliphatic polyisocyanates. It has good hardness, good flexibility, chemical corrosion resistance, outstanding weather resistance, plump and bright, good drying, and fast surface drying. , No dust and other characteristics, it is the choice of topcoat in the current heavy corrosion protection coating system.

Polyether polyurethane coatings have excellent alkali resistance, cold resistance and flexibility, and can be used as anti-corrosion coatings and concrete surface coatings. Due to the existence of ether bonds, the coating film is easy to decompose and lose light under ultraviolet radiation, so it is only suitable for indoor use.

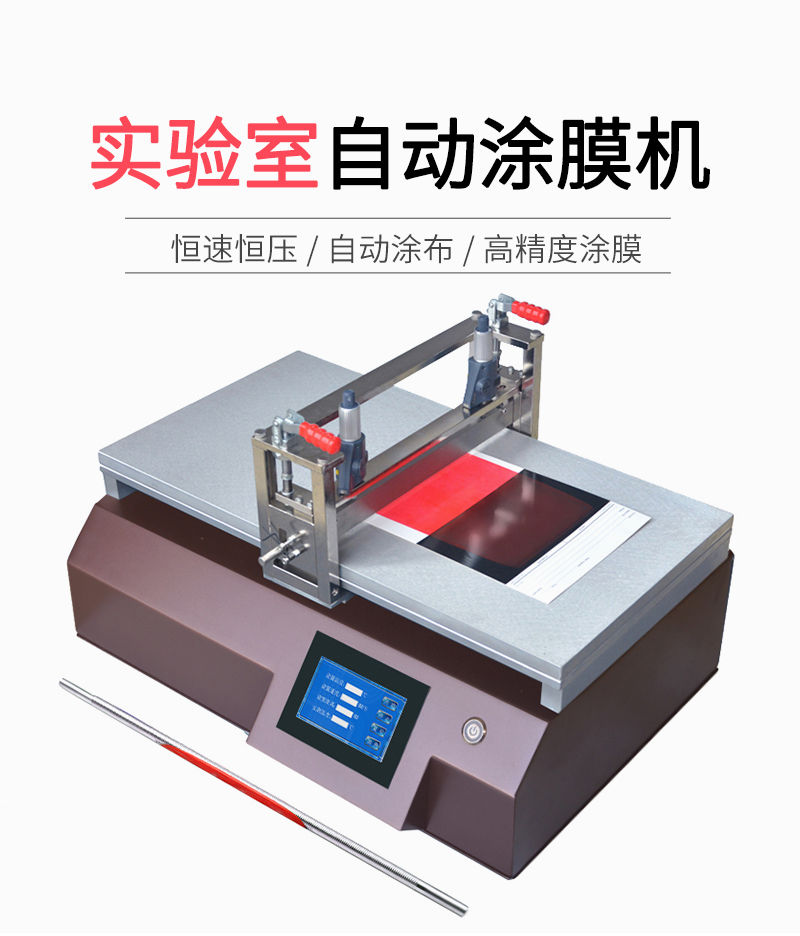

Under what circumstances should the film coating machine be used?

1. Ultra-thin coating film: under constant speed and constant pressure, the error of coating film can be reduced

2. Thin film substrate coating: it is difficult to ensure smooth film coating, which affects the effect

3. The coating material needs to be heated: a certain temperature is required to maintain a molten state

4. Multi-layer coating film: if one layer is not scratched well, it will be completely useless later