When spraying and cleaning metal surfaces, a certain surface roughness or surface profile is obtained. Due to the formation of roughness, the area of the metal surface will increase significantly and many anchor points will be obtained. Of course, the greater the roughness, the better. Because the coating needs to be able to cover the peaks of the roughness, the greater the roughness, the thinner the film is likely to be at the peaks. In addition, the greater the roughness, the lower the corrosion resistance and adhesion of the film due to poor penetration of the coating on the substrate.

The concept and measurement method of surface roughness are described in 1~4 of ISO 8503. A noun used to represent the concept of surface roughness.

For the surface roughness of blasting, we usually use r. Generally known as sandblasting roughness, Rz=(4~~6) × Ra, usually the maximum value is 6.

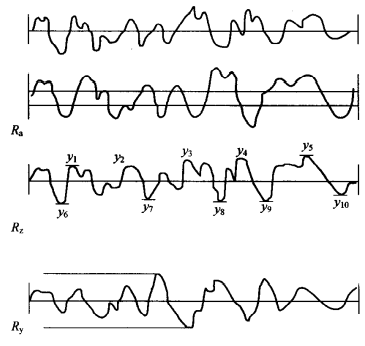

R a The average distance from the peak and trough to the center line

The early mean value of Rz from the peak to the trough, 5 points are taken from the top and bottom, Rz =1/5(y1+y2+...+y10)

The maximum value from the Ry peak to the trough, also called Rmax, can be measured by the stylus method

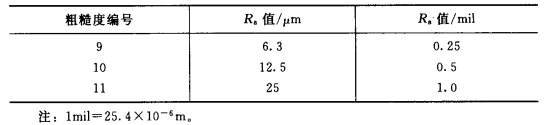

In the Rugotest No. 3 standard, R a is used to describe the roughness of the surface

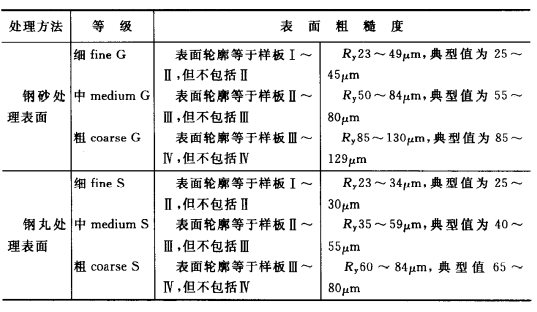

ISO 85031 divides the surface roughness template into two types: steel grit (template G) and steel shot (template S) spraying treatment. Each surface roughness sample plate is divided into 4 pieces (Ⅰ~Ⅳ).