Surface roughness refers to the micro-geometric features formed by small distances and grooves on the machined surface. Roughness can be divided into maximum roughness and average roughness (also known as centerline average roughness). The maximum roughness refers to the maximum vertical distance between any peak and the trough near the straight line, and the average roughness refers to the average vertical distance from each point on the polished surface to the center line.

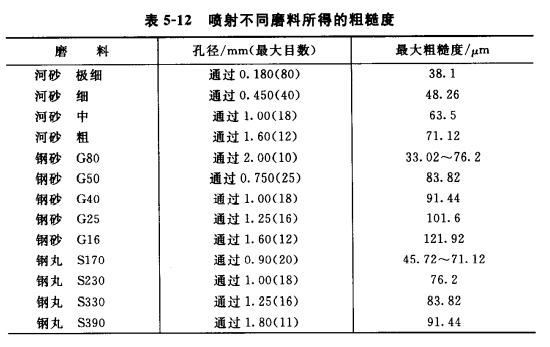

The roughness of the workpiece surface is related to the process parameters such as the particle size, shape, material, spraying angle, distance, and action time of the abrasive. Abrasive particle size has a great influence on roughness.