Coating defects can have many causes and more experience is needed to identify the correct cause. Poor application or spraying procedures can cause multiple coat problems. If the spraying equipment is not maintained properly or the construction personnel are inexperienced, there will be problems in the construction. It is difficult for inexperienced builders to avoid defects, but even experienced builders cannot avoid certain defects.

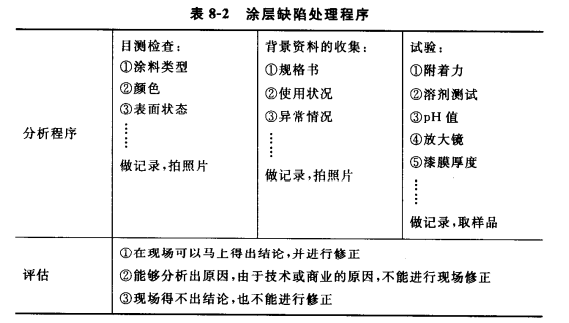

Additionally, weather conditions can have a significant impact on the results. By understanding the conditions that lead to these defects, you can avoid them in the future . In order to find out the cause, it is necessary to carry out systematic work, including one or more of:

1. Visual inspection

2. Collect historical information

3. Analysis of coating system

4. Judgment of stratum depression

When dealing with problems, there may not be documents and materials available for reference. In this case, finding the type of coating system is a good place to start. Additional information can be obtained by analyzing the general type of paint. This can be analyzed by high-end laboratory methods. However, simple outdoor analysis methods are also useful. Coatings have different curing mechanisms and a simple test method using a strong solvent can determine the type of coating. Depending on the paint curing/drying mechanism, the following reactions can be obtained on paint chips and paint, the necessary tools are:

1. Cotton

2. Strong solvent (MEK reagent)

If the cured paint is a fragment of paint, it can be placed in different types of solvents to determine its curing and drying mechanism. The key is to explore what happens to the paint chips, since a paint system can include several different paint types:

1. If the paint is dissolved in a solvent, it is a physically cured paint, such as acrylic resin paint

2. If the paint does not dissolve directly, but has bubbles or swelling, it can be inferred that it is an oxidative drying paint, such as an alkyd resin paint

3. No bubbles or swelling, indicating that it is a chemically cured coating, such as epoxy resin coating. It is important to give these tests sufficient reaction time. If an old oxidatively dried paint is not given sufficient reaction time, it will react very close to a chemically cured paint.

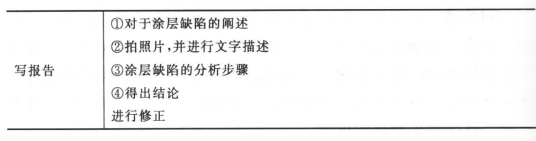

In order to find out the cause of coating defects, systematic work should be carried out. This includes multiple programs.