Defects in the coating, no matter how small, can ultimately render the metal substrate vulnerable to corrosion, negating the purpose of the protective coating.

Traditionally, armor was considered only as strong as its weakest point, highlighting the significant danger of any subsequent breach. Cracks in body armor can have life-threatening consequences, no different than holes caused by cracked protective coatings.

Even a small weakness in the coating can expose the underlying substrate, making the destructive effects of corrosion and erosion rendering the coating redundant.

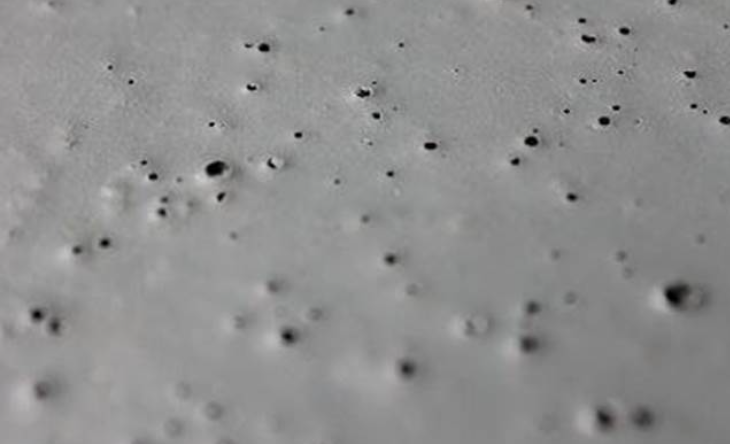

In the coatings industry, these defects are known as holidays, which are areas of the substrate that have not been properly coated, subsequently creating defects in the coating. Skips include omissions, insufficient coating thickness as well as inclusions and pinholes, all of which are recorded as abnormal.

Common causes of leaks

Skips can occur due to applicator errors or lack of knowledge of the coating application process. This includes an understanding of environmental conditions that can affect and overall hinder applications. (Be sure to read Service Requirements and Environmental Factors Defining Coating Specifications for more information.

A common environmental cause of slippage is insufficient coating viscosity, which can undermine overall application success. Extreme low or high temperature conditions can cause the coating to become too viscous or runny for proper application. Subsequently, the coating forms sags and curtains that eventually lead to omissions or skips within the coating structure. Adding an anti-sag agent may help prevent sagging.

During application, the properties of the coating can also increase the likelihood of holidays after the coating has cured. First, insufficient or incorrect mixing of coating ingredients can result in areas that fail to cure, resulting in disbonds and other coating defects. Over-mixing the coating prior to application will allow too much air to bind to the product, creating a large number of air pockets.

Mainly pinholes are formed when air bubbles rise to the surface of the coating and burst, and are not resealed by the coating itself. These tiny pores can simply be confined to the top layer of the coating, or go right through both coats, exposing the bare substrate.

When brushing the surface, the applicator needs to be sure to apply two coats. After the base layer, a second coat will need to be applied perpendicular to the original coat, thus covering any potential leaks that exist. If this method is not used, existing defects such as pinholes may not be covered.

Coating errors also occur in inaccessible areas where it is difficult to apply the coating evenly to the substrate. In good practice, coaters and coating inspectors should use mirror access methods to detect and repair coating holidays and pinholes that occur in hard-to-reach locations.

False coating detection equipment and method

Since most coating defects cannot be found visibly, special inspection equipment and techniques are used to locate coating anomalies.

Essentially, a coating is an insulating product that protects the conductive metal underneath. Spark Detectors use electricity to locate film anomalies by passing an electrical current through the coating to form a closed circuit beneath the substrate. High-low pressure instruments can be used to identify anomalies; however, each variable needs to be specifically matched to the application, depending on multiple variables.

For example, environmental conditions need to be suitable for effective holiday testing of surfaces, especially in terms of surface condition. The importance of a dried and cured coating to a positive test result cannot be overemphasized, otherwise entrapped solvent or uncured areas still present in the coating may provide false readings.

Typically, either a low pressure wet sponge test or a high pressure spark test is used, each with distinctly different capabilities in terms of functionality. (For more information, see Tools and Tips: Holiday Detection on Coated Steel and Concrete Substrates. Obviously, significant differences involve the voltages of the two devices; however, this does affect the type of each coating.

The manufacturer's guide states that the low pressure wet sponge Tester is only recommended for coatings with a maximum dry film thickness of 500μ (microns). For coatings thicker than 500µ, a high voltage Detector device should be used (assuming the coating is compatible).