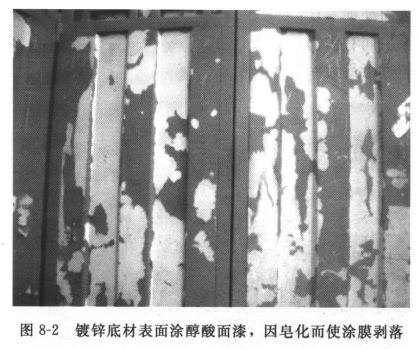

saponification

Oil-based paint, alkyd resin paint, phenolic resin paint, and epoxy resin paint cannot be directly painted on the galvanized surface, otherwise it is easy to have a saponification reaction with zinc, resulting in peeling off of the paint. Therefore, phosphating primers are usually applied on the surface of galvanized parts, or epoxy zinc phosphate coatings are used to ensure the adhesion of subsequent coatings. Likewise, these coatings cannot be applied directly to zinc-rich painted surfaces. Epoxy zinc-rich paint or inorganic zinc-rich paint surfaces are usually coated with vinyl coatings or high-performance epoxy and polyurethane coatings.

Bite the bottom

Undercoating occurs mainly when coatings containing strong solvents are applied to the surface of oxidatively dried coatings. Strong solvents will bite off the previous coat, and over time the adhesion between the coat and the substrate will be lost. Such as epoxy coatings, chlorinated rubber coatings, polyurethane coatings, etc., are prone to bottoming when applied on the surface of alkyd coatings. Pay particular attention to this problem when refinishing and painting old coatings. First understand the previous coating system. In actual painting, a small area test can be carried out to observe the effect. Other causes could be wax on the surface, insufficient drying of the previous coat, or insufficient adhesion between coats.