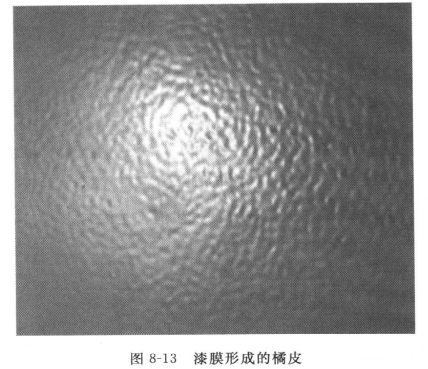

orange peel

Orange peel is a cosmetic coating defect. As the name suggests, the coating has an orange-peel finish. Orange peels can form in many ways:

①Paint viscosity is too high;

② The solvent evaporates too fast;

③The Spray Gun is too close to the surface;

④ The atomization pressure is too low.

According to the different reasons for the formation of orange peel, different methods should be used to avoid the formation of orange peel, such as adding an appropriate amount of thinner and using appropriate spraying techniques.

Once the orange peel has formed, it can be applied with a brush while the paint film is still wet. If the paint film has cured, smooth it with sandpaper or sandpaper

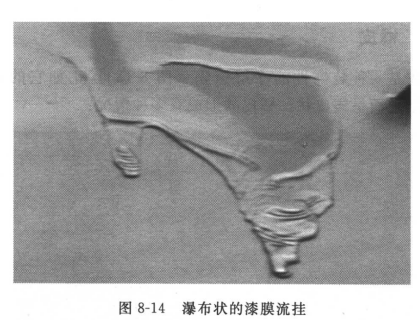

Sagging

Sag is the flow of a painted surface and is as serious as a curtain. The driving force for sagging is gravity. If the wet film thickness is too high, it will flow down vertical planes or corners. Sag usually occurs because of:

①The paint film exceeds the specified dry film thickness;

②Excessive addition of diluent in the paint;

③The Spray Gun is too close to the surface of the object to be coated;

④The spraying method is incorrect;

⑤The temperature is too high, causing the coating film to fail to hang on the surface;

⑥After the storage period, the anti-sagging performance of the coating will decrease;

⑦ Insufficient dosage of thixotropic agent or wrong thixotropic agent;

⑧The surface of the object to be coated is too smooth;

⑨The two-component coating has exceeded the applicable period, resulting in a decrease in the anti-sagging performance.

The measures to prevent sagging are as follows:

① Use the correct nozzle size and spray pressure to ensure the correct distance between the Spray Gun and the substrate;

② When preparing paint, avoid adding diluent to reduce viscosity during construction;

③Choose a suitable thixotropic agent (for example, hydrogenated castor oil will fail if the temperature exceeds 40°C);

④ The paint film thickness used should be considered when preparing the paint, such as the typical paint film thickness of the ship's ballast tank.

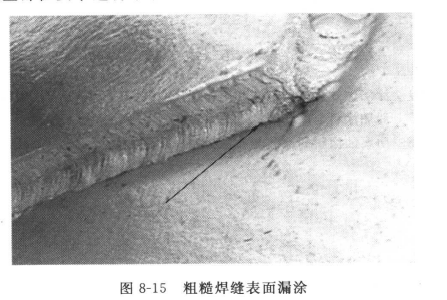

leak coating

A holiday is an area of a painted surface that is not painted, or has insufficient thickness due to insufficient overlap. These sections need to be marked and then recoated to the specified film thickness.

As a rule of thumb, some places, such as the back of flat steel, rough welds, cuts and free edges, or other places that are not conducive to spraying, are particularly prone to poor paint film quality, and these places require strip precoating.

Coating defects at these locations are usually pin-like spots. This is a common problem caused by construction negligence. If the Spray Gun is tilted up and down, the upper and lower paint films will be too thick. If the gun does an arc at low speed, the paint film will be too thick in the middle and thinner in the firing and closing parts. Each shot needs to be ground 50% to avoid missing coating.