The ISO 12944 standard "Paints and varnishes - Corrosion protection of steel structures by protective paint systems" is rapidly becoming the standard for corrosion control worldwide and rapidly replacing regional corrosion control standards. It is useful for owners of assets such as pipelines and storage tanks that have a maintenance schedule.

ISO 12944 gives you...

• ...confidence in taking specified corrosion control measures.

• ...provides the possibility of a standardized approach for the selection of coating systems.

• ...the opportunity to verify the suitability of the proposed coating system for its purpose.

ISO 12944 has 8 parts, namely:

Part 1: General Introduction

Part 2: Environment

Classification Part 3: Design Considerations

Part 4: Types of surfaces and surface treatments Part 5: Protective paint systems

Part 6: Laboratory performance test methods and related evaluation criteria

Part 7: Execution and supervision of paint

Part 8: Developing specifications for new work and maintenance

ISO 12944 lists several different examples of coating systems based on the corrosiveness of the environment and expected durability. This information is provided in Tables A.1 to A.8 of Annex A to Part 5. These systems have a proven track record. However, the standard is not intended to be a complete list of all available systems.

To understand it, some background in coatings is necessary.

How to choose a coating system for your factory?

(steps taken directly from ISO 12944)

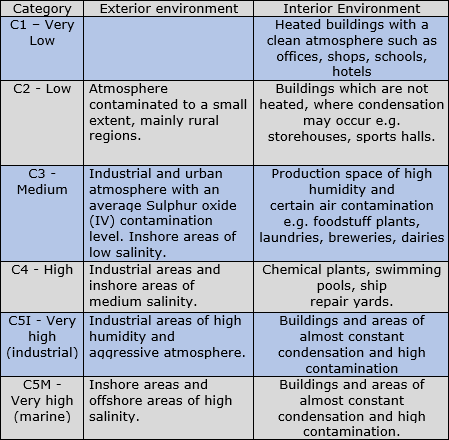

Step 1 Determine the corrosivity category of the environment in which the structure will spend most of its time.

ISO 12944 (Part 2) lists the corrosivity of environments according to the following table:

On the other hand, for underwater or buried structures, ISO 12944 provides the following classifications:

Im1 – freshwater (eg: Instalaciones rivereñas, plantas hidroeléctricas)

Im2 – seawater or brackish water (example: computers, muelles, estructuras offshore, pasos de agua)

Im3 – Buried (eg: underground storage tanks, buried pipelines, stilts)

Step 2 Determines whether there are any special conditions (called "microclimates" in ISO 12944 part 2) that lead to higher corrosivity.

Step 3 Select the desired coating system durability.

a) Low (L): 2 to 5 years;

b) Medium (M): 5 to 15 years old;

c) High (H): More than 15 years.

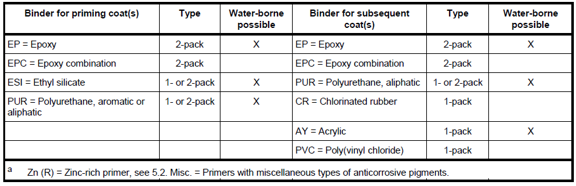

See Appendix A for Step 4 related forms. Tables A.2 to A.5 provide recommendations for different generic paint systems for corrosivity categories C2 to C5, while Table A.1 provides an overview of the contents of Tables A.2 to A.5.

Step 5 Identify the coating system with the desired durability in the table.

Step 6 Choose the best system, keeping the surface preparation in mind.

Step 6 According to ISO12944, "Consult the paint manufacturer to confirm the selection and determine the commercial paint system corresponding to the selected paint system"

Each manufacturer produces one or more coating systems according to ISO 12944. This means that each manufacturer has multiple brands of primers, intermediates and finishes.

Some manufacturers have used the same system for similar applications so many times that the systems have begun to have their own names. For example, almost all manufacturers have a "tank lining" system.

In practice, the durability of some systems far exceeds the specified 15 years. ISO 12944 states: "In general, increasing the total dry film thickness and number of coats will prolong the durability of the coating system. In addition, when such systems are used in less corrosive environments, the corrosivity category is selected "higher than" envisaged The system will provide higher durability.

example

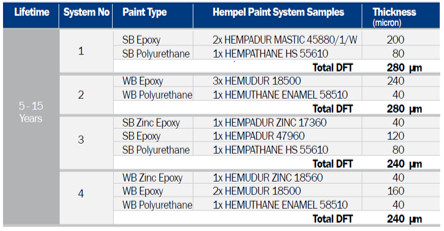

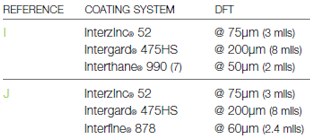

Let's verify the paint system proposed by Hempel, PPG Industries and International Coatings for a steel structure located by the sea.

Corrosive category: C5M

Durability: Moderate

international paint

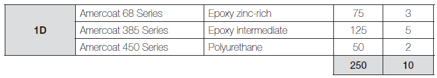

PPG Industries

Let's check against ISO 12944

Let's look at the C5M category in Table A5 of ISO 12944 (remember this table is for low alloy carbon steels prepared to Sa 21/2, rust protection class A, B or C). The proposed system is equivalent to system A5M.05 contained in the ISO standard.