What is a cross-hatch adhesion test?

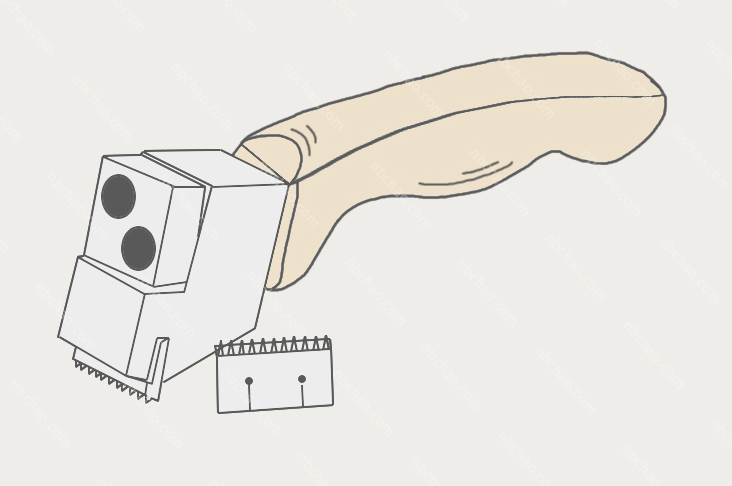

The cross-hatch test is a method of determining the resistance of paints and coatings to separation from the substrate by using a tool to cut a rectangular grid pattern in the coating, penetrating into the substrate. In this way a quick pass/fail test can be accomplished.

The purpose of the adhesion test

The basic goal of adhesion testing is to generate coating failure. The coating under test may exhibit interfacial failure between the substrate and coating or between individual coatings in multi-layer applications. Coatings can also undergo cohesive failure within specific layers.

How to conduct an adhesion test?

In this test, a coated specimen is biaxially stretched a given distance in a suitable machine, tape is applied to the deformed area (dome) and then removed, and the amount of coating removed is compared to a photographic standard to determine Coating adhesion rating.

How to do crosscutting testing?

X-cut the substrate using a carbide-tipped tool. Pressure sensitive tape is applied over the incision. Smooth the tape into place by using an eraser on the cut area. Remove the tape by quickly pulling the tape back on itself approximately a 180° angle.

How to conduct a cross-hatch adhesion test?

First, cross lines are cut in the finished film on the substrate with a cross line cutter. Then brush the cross-hatched area. Apply cross-hatch tape to the area and pull off. Finally, compare the cross-hatched test area to the ASTM adhesion standard below right.

How do you test powder coatings?

Gloss Measurement The gloss of a powder-coated finished part is verified by measuring the specular reflection of its surface. The test is performed using a gloss meter that shines light onto the surface of the part at a fixed angle and then measures the amount of light reflected from it.

How to test bond strength?

Adhesion is the strength of the bond between the tape and the surface to which it is applied. To measure adhesion, the tape was applied to a stainless steel panel. Then remove the tape. The force required to remove (or peel) the tape determines how well it adheres.

How do you know if it's powder coat or paint?

One way you can tell is if it's shiny, it could be paint. Powder coat has a semi-gloss look and may be a bit rougher than paint.

How are cross-hatchers used for adhesion testing?

Cross-hatch/hatch-hatch: A quick, low-cost visual comparison method for paint and powder coatings up to 250 microns (10 mils) thick. Coatings are diced to reduce lateral adhesion and adhesion is evaluated according to ISO, ASTM or corporate standards.

How is the cross-hatch adhesion test used for corrosion resistant coatings?

In order for corrosion resistant coatings to function properly, they need to adhere to the surface to which they are applied, and cross-hatch adhesion testing can determine whether a coating is properly adhering to its substrate. ASTM D3359 is known as the Standard Test Method for Measuring Adhesion by Tape Test.

How to measure the adhesion of a coating system?

Use the Appropriate Method: ASTM D3359 describes two test methods for evaluating tape adhesion of coating systems: Method A (X-cut tape test) and Method B (Cross-cut tape test). The method chosen is based on the total thickness of the coating system to be evaluated.

Which is the test standard for measuring adhesion?

ASTM D3359 is a standard test method for measuring adhesion by tape testing. This test evaluates the adhesion of film coatings to metal substrates by applying and removing pressure sensitive tape over a cut in the film.

Test Methods

In an area of at least 10 x 10 cm, use a cutter or suitable metal blade to make a grid incision down to the substrate. Create evenly spaced cuts (8-10 mm) in both horizontal and vertical directions to create a lattice pattern on the surface of the test area. Cover the cut area with tape and remove with force. Observe the area to determine the result.

standard

ASTM D3002-07 – Standard Guide for Evaluation of Coatings on Plastics

ASTM D 3359-09e2 – Standard Test for Measuring Adhesion by Tape Test

Method ISO 2409:2013 - Paints and varnishes - Cross-cutting t

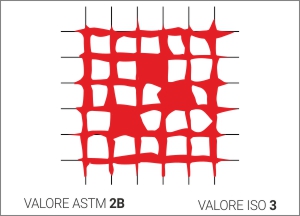

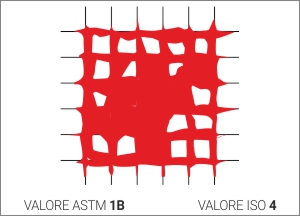

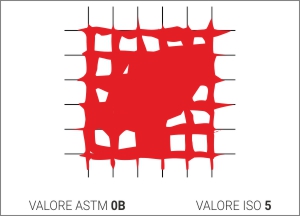

Test Results

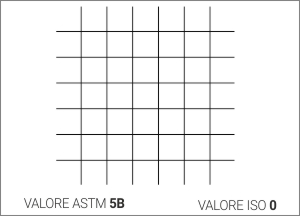

Adhesion is classified according to the standard in the following grades:

The edges of the cutouts are completely smooth; none of the squares in the grid are separated.

After the necessary preparations, the walls are suitable for painting.

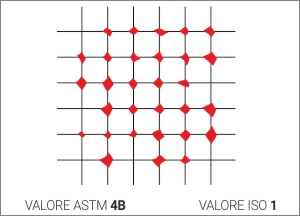

Small flakes of coating flake off at intersections. 5% of the cross-sectional area was affected.

After the necessary preparations, the walls are suitable for painting.

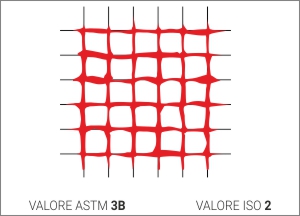

The coating flakes off in small flakes along the edges and intersections of the cuts. Between 5% and 15% of the cross-sectional area is affected.

After the necessary preparations, the walls are suitable for painting.

Partial or complete peeling of paint along edges and/or partial or complete peeling of some squares. Between 15% and 35% of the cross-sectional area is affected.

Apply a firming fixer primer to the grid before painting and repeat the test after drying to assess adhesion. If the values improve, the walls can be painted after applying a fixing primer. Otherwise, scrape some or all of the surface before repainting.

Paint flakes off in large strips along the edges of the cut and/or some squares are partially or completely peeled off. Between 35% and 65% of the cross-sectional area is affected.

Part or all of the surface will need to be scraped prior to painting.

Flaking of any degree, cannot fall into Category 4, in which the separated paint exceeds 65% of the cross-sectional area.

The surface needs to be completely scraped before painting.