One of the basic tests that can be performed on a product is a tensile test to check the product's resistance to breaking. Hold the specimen under tension to practice opposing forces acting on opposite faces in an attempt to pull the specimen apart. These tests are easy to set up and complete, and reveal many characteristics of the product being tested. Tensile testing is essentially the opposite .

Purpose of tensile test

Typically, tensile tests are designed to be run until the specimen breaks or fails at a specified load. Values calculated from such tests can vary but are not limited to tensile strength, elongation, ultimate strength, electrical modulus, yield strength, and strain hardening. Measurements taken during the test reveal the behavior of the material under tensile load.

Plastic Tensile Test

Composites and plastics are polymers to which substances are added to improve performance or reduce cost. Plastics can be pressed or cast or extruded into sheets, films or fiber reinforced panels, glass, pipes , fibres, bottles and boxes. Thermosetting or thermosetting plastics can be brittle or hard and resistant to high temperatures. Thermosets include polyester, epoxy, polyurethane, phenolic non-meltable, non-deformable, and polyurethane. Polymers and plastics can be tensile tested to measure product quality. Tensile testing measures the weight required to and measures the sample elongation or stretching to this breaking load. The resulting data helps identify product quality and quality control inspections of materials.

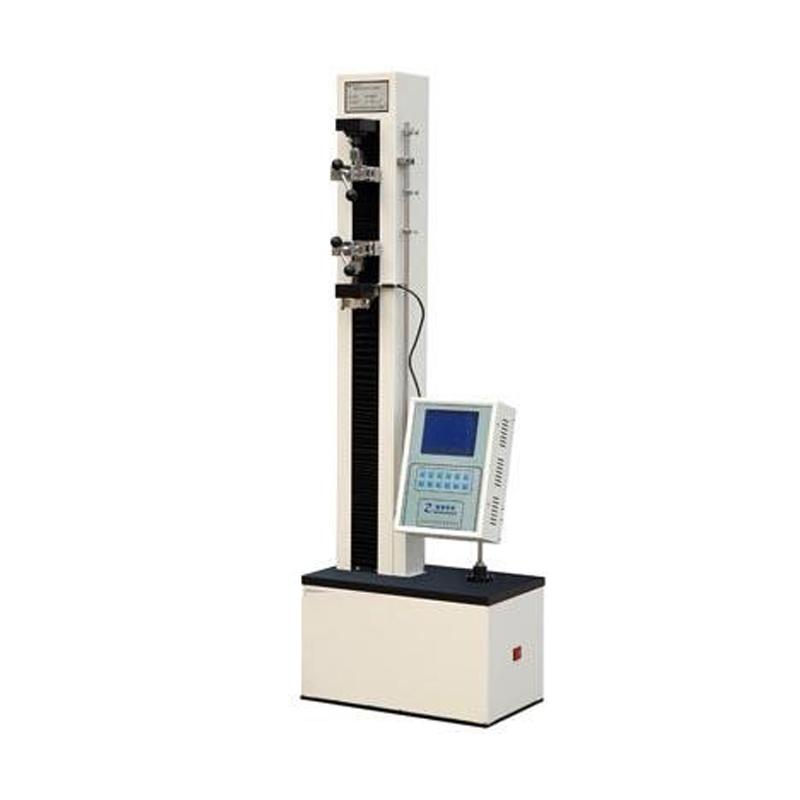

Plastic Tensile Testing Instruments, Universal testing machines provide constant elongation because plastic tensile testing behavior depends on the speed of the testing machine. The specimens loaded on the machine are set up according to ASTM, DIN, ISO tensile specimen dimensions. Plastic testing machines should always rely on standard terms and conditions. According to ASTM D638, the tensile testing standard for plastics facilitates the measurement of strain below the 20% elongation value. High strain can be measured by machine, digital reader. Thin-sheet sample testing was performed in accordance with standard ASTM D882.