Whether the quality of the coating product is qualified can be determined by testing its appearance and transparency, color, fineness, viscosity and solid content and other technical items.

1. Determination of appearance and transparency

It refers to the determination of whether paints and thinners contain mechanical impurities and the degree of turbidity presented. The determination method is as follows: the sample is loaded into a dry and clean colorimetric tube, the temperature is adjusted to 25±1 °C under the transmitted light of the dark box to observe whether it contains mechanical impurities, and at the same time, compared with a series of standards with different degrees of turbidity (colorless part for colorless part, colored part for colored part), select the primary standard solution close to the sample. The transparency grade of the specimen is directly expressed in the grade of the standard. During the test, if the standard solution is found to have cotton wool-like suspension or precipitation, it can be shaken and then compared with the sample. When measuring the appearance and transparency (testing instrument: transmittance meter), if the sample is turbid due to low temperature, it can be heated to 50~55 °C on a Water Bath for 5 minutes, then cooled to 25±1 °C, and then held for 5 minutes before measurement.

2. Determination of color

The determination of the color of the paint (testing instrument: Color Chart, should be determined according to GB1722-79, "Varnish, Clear Oil and Thinner Color Determination Method"). For pigment-free coating products, if the depth of their primary color is checked, the specimen can be compared with an iron-cobalt Colorimeter, where the same asThe color of the iron-cobalt Colorimeter is the closest to the color of a certain color scale solution, which represents the color number of the sample, the larger the number, the darker the color, and vice versa. Determination method: The sample is loaded into a washed and dried test tube, and compared with the iron-cobalt Colorimeter under the transmitted light of the dark box at 25±1 °C, two samples with similar colors or a standard color scale solution with the same color as the sample are selected, and the color grade of the sample is directly indicated by the standard color scale. If the hue is different, the shade of the color can be compared. During the test, if the sample is turbid due to low temperature, it can be heated to 50~55°C in a Water Bath for 5 minutes, then cooled to 25±1°C, and then held for 5 minutes before measurement.

3. Determination of viscosity

The instrument for measuring the viscosity of the coating can use the coating -1, the coating -4 falling ball viscometer, etc., while in the automobile coating construction, the coating -4 viscometer (No. 4 cup viscometer) is mainly used. Test method: Put the sample into the Viscosity Cup, scrape the bubbles and excess sample into the groove around the cup with a glass rod (plug the leakage hole in the lower part of the cup with your finger before pouring the sample), and then release your finger to make the sample flow out, and start the stopwatch at the same time, stop the stopwatch when the sample flow is interrupted, and count the outflow time seconds, which is the viscosity of the sample. The test temperature is 25±1°C, and the average value is generally taken three times.

4. Determination of fineness

The fineness determination of the coating (testing instrument: Fineness Meter) is an important index to check the size and uniformity of particles such as pigments, physique pigments and mechanical impurities in the pigment or primer, which is measured by a scraper Fineness Meter and expressed in microns. Such as the determination of topcoat (base paint), with50 micron scraping Fineness Meter, 100 micron scraper fineness gauge for primer and intermediate coat paint. Determination method: First use a small paint knife to fully stir the paint, and then use a knife to pick an appropriate amount of paint and drop it into the deepest part of the groove of the scraper Fineness Meter for a few drops, so that it can fill the groove slightly redundant. After that, with both hands of the scraper, scrape parallel from the deep part of the groove (head) to the shallow part, and when scraping, the paint sample fills the groove and leaves no paint on the flat plate. Immediately (within 5 seconds) after scraping, make the line of sight at a 15° angle to the plane of the trench, observe the uniform exposure of the particles in the trench with the light, and write down the scale on the scraper Fineness Meter (accurate to the smallest scale).values) must not exceed three particles in the range. Generally, the scrape is tested three times, and the average scale value is taken.

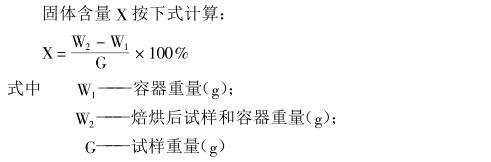

5. Determination of solid content

The determination of the solid content of the coating should be determined according to GB1725 "Determination of the Solid Content of the Paint". That is, the ratio of the weight of the residue to the weight of the sample after the coating is heated and melted at a certain temperature, expressed as a percentage. Determination method: First, the dry and clean Petri dish was baked in a 105±2°C oven for 30 minutes, then taken out and put into a dryer, cooled to room temperature and weighed. After that, take a sample with a grinding drip bottle and weigh 1.5~2g of the sample (perchloroethylene paint) by the reduction method

Sample 2~2.5g, 4~5g of lacquer with solid content of less than 15% such as nitro paint, place it in a weighed petri dish, make the sample evenly spread at the bottom of the container, and then put it in the specified range of the paint baking temperature (nitro, perchloroethylene, acrylic paint 20±2 °C, amino, polyurethane, alkyd and other paints 120±2 °C within the constant temperature blast oven for a certain time, take it out and put it in the dryer to cool to room temperature and weigh. The weight difference of the secondary weighing is not more than 0.01g (the total weighing is accurate to 0.01g).

The test results were taken as the average of the two parallel tests, and the relative error of the two parallel tests was not more than 3%.

6. Determination of putty consistency

The determination of putty consistency is pressedThe determination method of GB1743-79 "Thick Lacquer and Putty Consistency Determination Method" takes a quantitative volume of sample, and after a certain period of time under fixed pressure, it is expressed as the diameter of the sample flow diffusion. Determination method: Take the sample and load the pump (test instrument) without leaving a gap, and then press the sample out of the pump with a pump plug. The sample of the cylinder is removed with a paint knife and placed in the center of the glass plate, and then another glass plate is gently placed flat on the sample, and then the code is pressed on it, and the stopwatch is started at the same time, and after 1 minute, the weight is removed to observe the scale of the sample flow spread on the cylinder at the glass place, and the number of centimeters in diameter is recorded, that isfor the test results. The test should be carried out under constant temperature and humidity conditions.