Human beings are all surrounded by different colors. Colors help define the product, such as blue for sky and red for blood . Color is also used to indicate the quality of the product, the purpose of the product and the type of product. Also, color is used to enhance the appearance of the product. Attractive colors help to grab customers' attention and influence their purchasing decisions. Therefore, manufacturers in different production verticals attach great importance to the color quality and appearance of their products. Bright colors indicate that the product is of acceptable , while dull colors indicate poor quality.

How to measure the color quality of a product?

To ensure the color quality of their products, manufacturers use color measurement solutions and improve the color quality . There are various attributes that affect the color quality of a product, such as hue, light, transparency, translucency, opacity , redness or bluishness, and metamerism of the product. Different quality defects create different problems in the product. One of the main defects that seriously affects product quality is metamerism. It is commonly found in the textile industry. Let us discuss this phenomenon in detail.

metamerism theory

Metamerism is a condition where a pair of objects are placed separately in different light to match the color consistency and color quality of the fabric. If the color appearance of two samples looks the same even under different lighting conditions (e.g. viewing one sample under D 65 artificial daylight and the other under tungsten light), then the product is good in terms of quality. On the other hand, under the same test conditions, if the samples are different, it will be considered as a defect of metamerism, and the color quality of the product is not good enough, and there are major defects in the product that cannot be ignored.

Metamerism problems in different industries

The metamerism problem creates a noteworthy problem for manufacturers in different production verticals such as textile, paint and plating, plastics, automotive, printing and packaging, etc. These industries have problems with metamerism because the same product is produced in multiple batches, and small changes in color mixing can cause large color defects and lead to the rejection of the entire batch. For example, the production of lengths of fabric and liters of single-color paint cannot be realized in one batch. In order to meet the needs of a large number of customers for a single color, manufacturers are forced to produce on a large scale and in multiple batches, which sometimes leads to inconsistent colors, resulting in the consequences of product metamerism, and is regarded as a major quality defect.

How to assess and resolve metamerism?

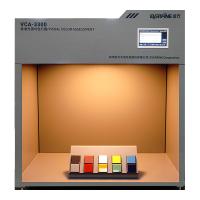

A method of identifying metamerism defects in fabrics and other products is the color matching cabinet. It is one of the color matching devices used to match colors under different lighting conditions. The test instrument consists of different lighting conditions, which can be used to match the color of the product under different . This testing is done on different products to ensure the material looks the same when used in all lighting conditions. Usually, the color matching cabinets are designed according to the spectrum of the United States, Europe and Asia, and manufacturers can easily purchase the instruments of the selected light according to their own regions, so as to ensure the color quality in a better and effective way.

The life of living beings is surrounded by different colors such as the color of flowers, the color of nature, the color of clothes, the color of gadgets, the color of tools, the color of food, etc. Constantly changing fashions, styles and trends force manufacturers to pay more attention to the quality of the products they manufacture, whether it is textiles, paints or plastics. Measuring product quality is a major task that manufacturers need to perform at every level of . The color matching cabinet is a testing machine used to check the color consistency of products. This testing machine is used to measure the color of different products under standardized atmosphere and different lighting conditions. Test equipment helps to resolve metamerism problems easily. The equipment is widely used in paint and electroplating industry, plastic industry, yarn and textile industry, paper making and packaging industry , automobile industry, etc.

Matching cabinets have been a favored machine over the years for their accuracy and durability. The test apparatus is equipped with five lamps, which are provided according to various standard test methods according to the color temperature and illuminance of the lamps. No matter what type of material you are testing. Whether it is ceramic, glass, wood, plastic, fabric or anything else, the color matching cabinet can help users test different samples and provide highly precise and accurate test results.