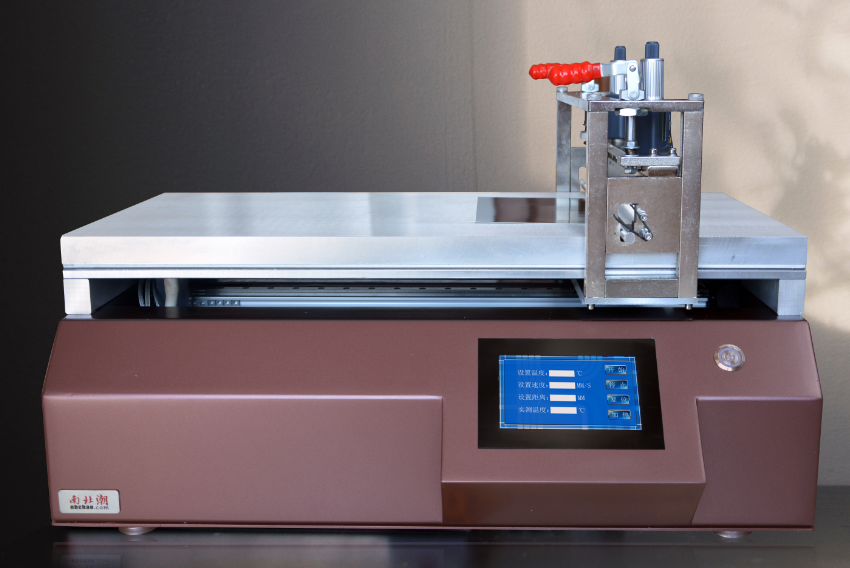

What is a laboratory coater?

A laboratory coater is an experimental instrument used for fine, uniform coating of a substance, such as a liquid or powder, in a laboratory environment. It is commonly used in several industries such as printing, coatings, textiles and electronics for research and development, quality control and production processes. There are several types including wire Bar Coaters, blade coaters, roll coaters and cord coaters. The type of coater used will depend on the type of substance being applied, the type of substrate, and the desired coating thickness.

Laboratory Film Applicators can be used to coat a variety of substances such as inks, paints, adhesives and coatings for electronic devices. They are accurate, repeatable and efficient and are often used to test and optimize coating formulations before Graduation up to production.

Using a laboratory coater requires careful attention to process parameters such as the speed of the coater, the gap between the coater and substrate, and the amount of material to be coated. Improper use or setting can result in uneven or uneven coating, which can affect the quality and performance of the final product.

How to use the film coating machine?

Using a laboratory Film Applicator requires the following steps:

Prepare the substance: Prepare the coating substance by diluting it to the appropriate concentration.

Prepare the Substrate: Prepare the substrate for coating, such as paper, plastic or metal.

Set coating parameters: adjust the speed of the coater, the gap between the coater and the substrate, and the amount of material to be coated.

Start coating: Start the coating operation and control the movement of the substrate to ensure the uniformity of the coating.

Inspect the coating: Check the thickness, uniformity and color of the coating.

Record data: record coating related data, such as speed, coating thickness, etc., for future comparison and improvement.

Cleaning and Maintenance: After coating, clean the applicator and surrounding area to ensure it is operating efficiently.

Note: The use of laboratory film coating machines requires compliance with certain safety rules, such as wearing personal protective equipment, avoiding contact with toxins, etc. In addition, operators of coaters need to be trained to ensure safe operation.

How to choose?

The following factors need to be considered in selecting the appropriate laboratory coater:

Application requirements: clarify the purpose and requirements of coating to determine the type and performance of the required coating machine.

Substrate Size: Select a coater that is suitable for the size of the substrate being coated.

Coating thickness: choose a coating machine that can coat to an appropriate thickness.

Functional performance: Select the function of the coating machine, such as coating speed, function of diluting substances, etc.

Capacity: Choose the appropriate coater capacity to meet the coating needs.

Price: Choose the right price to ensure the desired coating machine cost performance.

Brand: Choose a coater of a familiar brand to ensure quality and reliability.

After-sales service: Choose a coating machine that provides good after-sales service to ensure the normal use of the coating machine.

Before choosing a coating machine, it is recommended to conduct detailed market research to compare the performance and price of many different coating machines to ensure the selection of a more suitable coating machine.