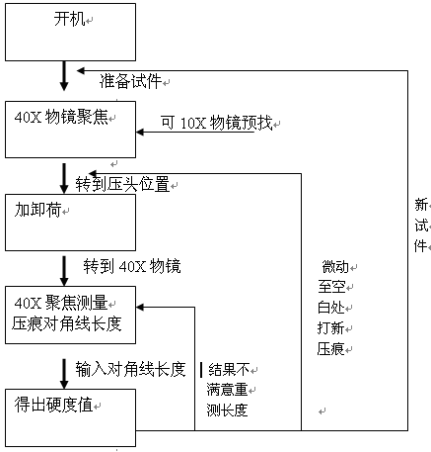

The working process of the Hardness Tester to measure the hardness

The specific measurement method of indentation

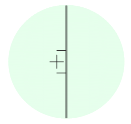

| 1. Observe the two engraved lines in the field of view from the eyepiece, and rotate the eyecup to make the engraved lines clear. Note: Rotating the eyecup may cause the image of the indentation to be blurred. After the two engraved lines are clear, turn the lifting wheel to make the image of the indentation clear. |  |

| 2. Turn the drums on both sides of the micrometer eyepiece to make the inner sides of the two reticle lines infinitely close, that is, when the light transmission between the inner sides of the two reticle lines is gradually in the critical state of light and no light, observe the zero mark on the measuring drum. Are the lines aligned. (This has been adjusted before leaving the factory, please do not adjust it at will, because everyone's vision is different). |  |

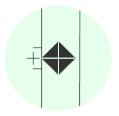

| 3. Turn the two drums of the micrometer eyepiece in the opposite direction, and the two reticle lines will gradually separate. Turn the left drum of the eyepiece so that the inner side of the left reticle is tangent to the left edge of the indentation. |  |

| 4. Turn the right measuring drum so that the inner side of the right engraved line is tangent to the right edge of the indentation, record the data as shown in the figure and input the value of the indentation length and press OK, and the D1 measurement is completed. |  |

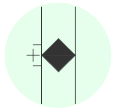

| 5. Turn the micrometer eyepiece 90° (note that it should be close to the eyepiece tube when turning), and turn the drum so that the inner side of the lower engraved line is tangent to the edge of the lower edge of the indentation. |  |

| 6. Turn the measuring drum so that the inner side of the upper engraved line is tangent to the upper edge of the indentation, see Figure 5.9, write down the data and input the value of the indentation length and press OK, D2 measurement is completed. The instrument automatically calculates the hardness value and displays it, the number of tests is automatically increased by one, and one measurement is completed. |  |

| 7. Calculation of the length of the indentation: the eyepiece measures the drum to rotate a circle of 50 divisions. When the inner side of the moving score line is tangent to the diagonal line of the indentation, read the number of full rotations (on the drum shaft) and the outer diameter of the drum. Number of cells on the circle. | |

| Example: If two full circles are rotated, there are 12 small divisions on the outer circle of the drum, then the total is 112 divisions, and it is sufficient to directly input 112 when inputting into the machine. (The actual length of the indentation diagonal: 0.25×112=56μm) |