A benchtop conductivity meter is an instrument used to measure the conductivity of a solution. The following are the selection points and precautions for this type of instrument:

select points

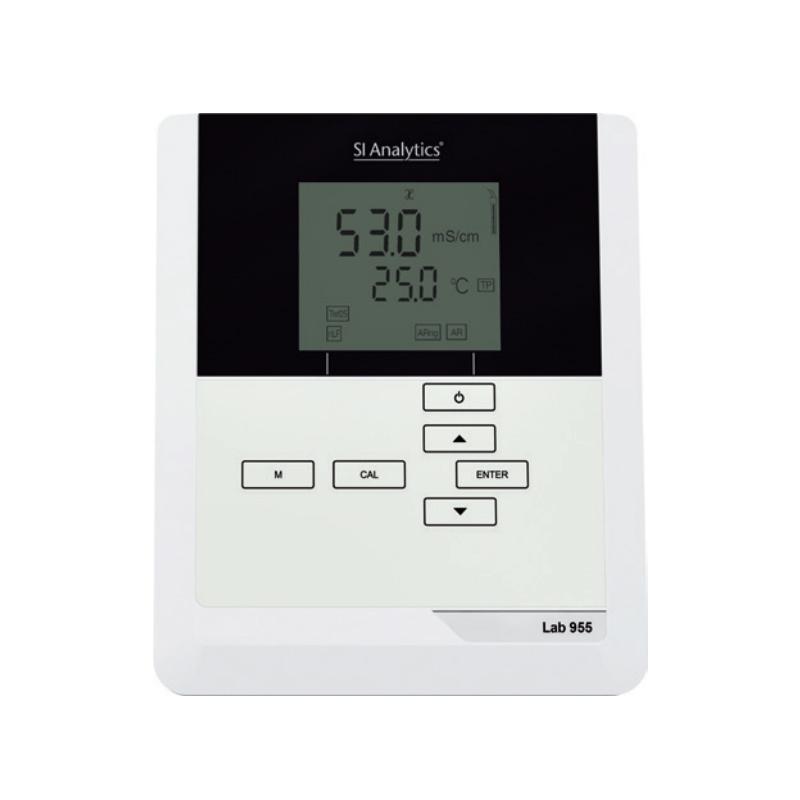

Measuring range: Different models of desktop conductivity meters can measure conductivity in different ranges. Choosing the right conductivity meter depends on the conductivity range of the liquid you want to measure.

Accuracy: Different models and brands of benchtop conductivity meters have different accuracy. If you need high-precision measurements, you should choose a more accurate instrument.

Automatic temperature compensation function: Some benchtop conductivity meters have automatic temperature compensation function, which can automatically adjust the conductivity reading according to temperature changes to improve measurement accuracy. If you need to measure the conductivity of liquids at different temperatures, you should choose a conductivity meter with this function.

Display: Make sure the benchtop conductivity meter you choose has a clear, easy-to-read display to make reading and recording measurements easier.

Data Storage: Some benchtop conductivity meters have data storage capabilities that allow the storage of multiple measurements. If you need to log multiple measurements, you should choose a conductivity meter that has this capability.

Precautions

Calibration: Benchtop conductivity meters require periodic calibration to ensure accurate measurement results. The calibration procedure provided by the manufacturer should be followed.

Cleaning: Before using the benchtop conductivity meter, be sure to clean the electrodes to avoid bias in the measurement results. The cleaning fluid recommended by the manufacturer should be used.

Proper use: The desktop conductivity meter should be used correctly according to the instructions in the operation manual, avoiding wrong operation or rough operation, so as not to damage the equipment.

Maintenance: Periodic maintenance of the device is required, such as replacing batteries or replacing worn electrodes. Maintenance should be carried out in accordance with the maintenance instructions provided by the manufacturer.