The scraper is a tool commonly used in laboratories for coating and evenly coating samples. The following are the selection points and precautions of the scraper:

select points

Wet Film Thickness: The wet film thickness of the drawdown.

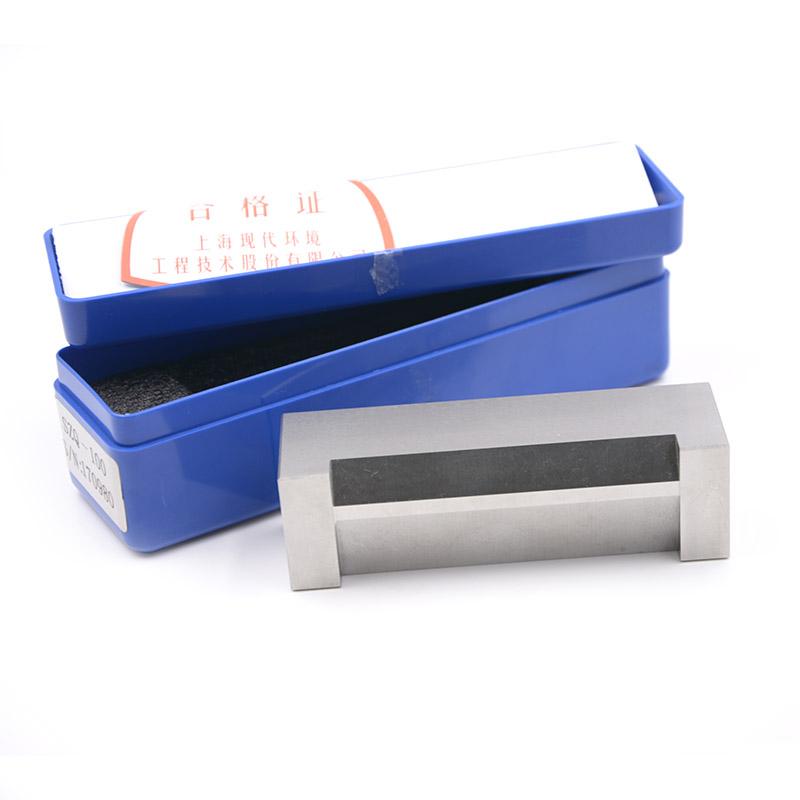

Material: Common scraper materials include stainless steel, aluminum alloy, plastic, etc. The choice of material should consider factors such as the nature of the sample, the use environment and experimental requirements.

Size: Choose the appropriate size of the knife coater according to the size, shape and coating area of the sample.

Squeegee coating shape: The shape of the squeegee coating is rectangular, square, triangular, etc. Choosing the appropriate shape can improve the coating efficiency and coating quality.

Flatness of the scraper coating board: The flatness of the scraper coating board surface has a great influence on the coating effect, so it is necessary to choose a scraper coating board with a high surface flatness.

Edge treatment of the scraper coating board: The edge treatment of the scraper coating board should consider its influence on the sample coating, and the edge should be smooth without burrs.

Precautions

Cleaning before use: Before use, it should be cleaned with pure water or an appropriate solution to ensure that there are no residual impurities.

Avoid collisions during use: Avoid collisions between the scraper and other hard objects during use to avoid scratches or deformation on the surface of the scraper.

Pay attention to the scraping speed: the scraping speed should be appropriate, too fast or too slow will affect the coating effect.

Pay attention to the coating thickness: the coating thickness should be uniform, not too thick or too thin.

Clean up after use: Clean up in time after use to prevent sample residue from affecting the next experiment.