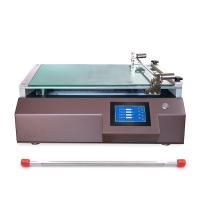

The wire rod vacuum adsorption film coating machine is a commonly used thin film preparation equipment, which is used to prepare thin films of various materials in the laboratory, such as metals, semiconductors, ceramics, etc. The following are the selection points and precautions of this equipment:

select points

Type of wire rod: select the appropriate type of wire rod according to the material to be prepared. Different materials require different wire rods, for example, metals require metal wire rods, and non-metallic materials require graphite or ceramic wire rods.

Wire rod diameter: The wire rod diameter determines the accuracy of the film thickness. In general, the smaller the diameter, the higher the film thickness accuracy. However, too small a diameter of the wire rod will also affect the preparation speed of the thin film.

Vacuum degree: Choosing equipment with high vacuum degree can better control the atmosphere in the film preparation process, and then obtain higher quality films.

Control system: Choose equipment with a reliable control system in order to better control various parameters of the preparation process, such as temperature, vacuum degree, wire rod position, etc.

Precautions

Safe operation: Wear protective gloves and goggles during operation to avoid radiation damage from high-temperature wire rods and vacuum adsorption.

Film material selection: Select the corresponding wire rod and vacuum degree according to the film material to be prepared.

Cleaning and maintenance: Clean up the equipment in time and keep the equipment clean to avoid impurities from interfering with the film preparation process.

Experimental environment: Choose a suitable experimental environment, such as a dry, dust-free, vibration-free environment, to obtain higher quality films.