Automatic Film Applicator is widely used in film Moulding. Film Moulding is the process of Spreader on the film surface to control the drug release rate, improve the stability of the drug and prolong the shelf life of the drug.

The following are some applications of Automatic Film Applicator on Film Moulding:

Drug film preparation: Automatic Film Applicator can be used to prepare different types of drug films, such as controlled release films, oral mucosal patches, etc. Drug films can make drugs easier to absorb, reduce adverse reactions, and enhance drug bioavailability.

Drug controlled release: Automatic Film Applicator can be used to prepare different types of controlled release films, such as delayed release, progressive release, gastrointestinal directional release, etc. This technology can improve the effect of the drug, reduce adverse reactions, prolong the action time of the drug, and reduce the dose of the drug.

Increased stability: The stability of the drug refers to the stability of the drug during storage and transportation. Automatic Film Applicators can be used to prepare drug films with excellent stability, such as anti-oxidation agent coating, moisture-proof agent coating, photoprotective agent coating, etc.

Protective drugs: Automatic Film Applicator can be used to prepare films for protective drugs, such as moisture-proof films, anti-light films, anti-oxidation films, etc. These films can reduce the exposure of water, rays of light and oxygen of the drug, thereby extending the shelf life of the drug.

In the laboratory, Automatic Film Applicator is usually used to prepare small batches of pharmaceutical films. The following is the general preparation process:

Prepare the drug: Select the drug that needs to be prepared into a film and prepare it in the desired dose.

Prepare the coating solution: choose the solution suitable for the drug and mix it in the desired ratio. The concentration of the solution needs to be adjusted according to the characteristics of the drug.

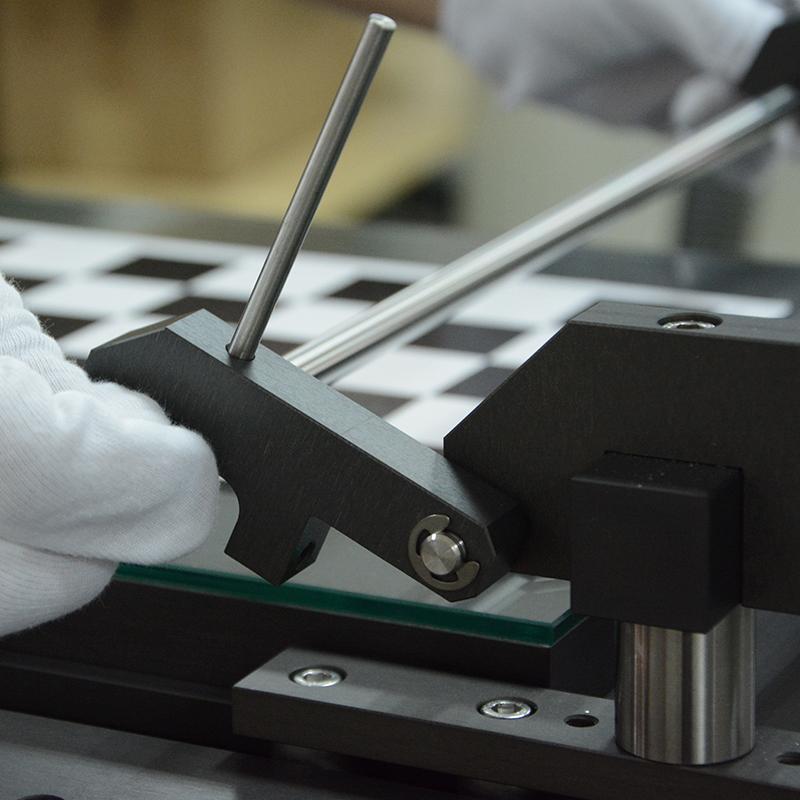

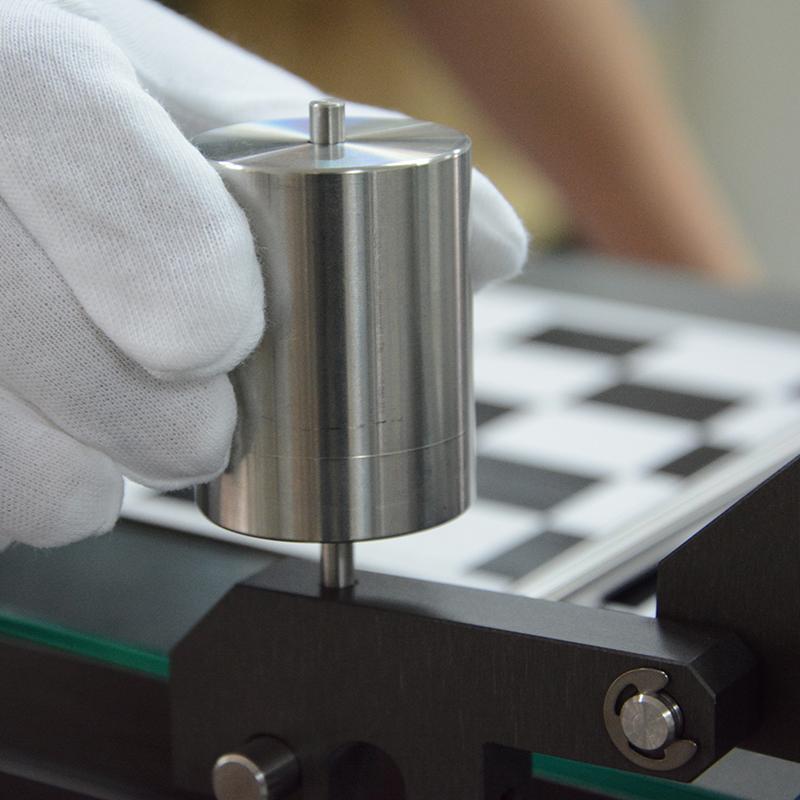

Prepare the substrate: Choose a suitable substrate, such as Glass or Silicon, to ensure that its surface is smooth and clean. The size of the substrate needs to be selected according to the experimental needs.

Adjust the viscosity of the coating solution: Adjust the viscosity of the coating solution to the appropriate level using a Viscometer or Miscellaneous instrument.

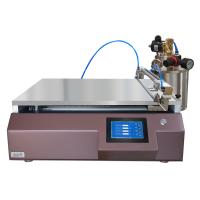

Adjust the parameters of the coating machine: According to the characteristics of the coating solution and the characteristics of the substrate, adjust the parameters of the coating machine, such as the position of the nozzle, the size of the nozzle, the lame plating speed, etc. During the coating process, it is necessary to control the uniformity of the coating and Film thickness.

Coating drug solution: Coating the drug on the substrate, usually by roller or scratch coating.

Drying film: The drug-coated substrate is dried in a drying chamber to remove moisture and form a film. The drying conditions need to be adjusted according to the characteristics of the drug and the substrate.

It should be noted that the process of preparing drug films in the laboratory needs to follow certain safety specifications and laboratory management requirements to ensure the safety of the experimental process and the accuracy of the experimental results. At the same time, it is necessary to pay attention to the daily maintenance and maintenance of the coating machine to ensure the normal operation of the equipment. In short, Automatic Film Applicator is widely used in film Moulding, which can help pharmaceutical companies prepare high-mass drug films, improve the stability and bioavailability of drugs, and thus improve the therapeutic effect of drugs.