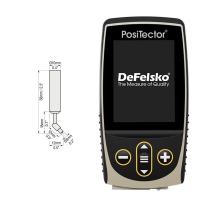

Digital Thickness Gauge is an instrument that can measure the thickness of various materials (such as metal, plastic, ceramics, etc.). It uses a high-frequency oscillating circuit and an induction coil to determine the material thickness and displays the result on a digital display. The following are the selection points and precautions of the digital display Thickness Gauge:

select points

Measuring range: Select the measuring range of the digital display Thickness Gauge according to actual needs. Different models of instruments have different measurement ranges, and an instrument suitable for the measurement object should be selected.

Resolution: Resolution refers to the smallest unit displayed by the instrument. Choosing an instrument with a higher resolution can improve the measurement accuracy. However, higher resolution instruments are usually more expensive.

Accuracy: Choosing a digital Thickness Gauge with high precision can improve the accuracy of the measurement results. Different models of instruments have different accuracy.

Display screen: Selecting a clear display screen can make operation easier. The large screen improves readability, making it easier to read measurement results.

Data storage and transmission function: Some digital display Thickness Gauges have data storage and transmission function, which can store the measurement results in memory or transmit them to computers or other devices. If long-term storage or further analysis of data is required, choose an instrument with this capability.

Precautions

Preparation before measurement: Before measurement, please ensure that the surface of the material to be measured is clean and smooth, and that the measuring head is clean.

Keep stable during measurement: During the measurement process, keep the instrument stable and avoid external interference (such as vibration, electromagnetic interference, etc.).

Selection of measurement range: Selecting an appropriate measurement range can improve measurement accuracy. Selecting a range that is too large or too small may result in loss of accuracy.

Instrument maintenance: When using a digital display Thickness Gauge, attention should be paid to maintenance, regular cleaning and calibration to ensure its accuracy and stability.

Environmental conditions: The digital display Thickness Gauge is suitable for measurement at room temperature. In high temperature, low temperature, humidity or other extreme environments, measurement accuracy may be affected, so use under these conditions should be avoided.